what is gyratory crusher

Gyratory Crushers of the Sierra Pinacate, Sonora

The gyratory crusher resembles a perforated mortar, either in slab or block form, in which a wooden pestle with a projection extending through the perforation

Learn More

How do a gyratory crusher work?

A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners. The inner cone has a slight circular movement, but it does not rotate. The movement is generated by an eccentric arrangement.

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

17/02/ · Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a

Learn More

Method for securing a gyratory crusher mantle - Google Patents

The head nut assembly for gyratory crusher which includes a shaft having a lower portion, a tapered middle portion and a threaded upper portion.

Learn More

What Type of Crusher Is Best for Primary Crushing?

Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry

Learn More

Superior™ MKIII Series primary gyratory crushers

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers

Learn More

Gyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn More

Gyratory crushers - Hardox Wearparts

A gyratory crusher is a mining or ore processing machine that crushes feed material between an eccentrically mounted cone and a fixed crushing throat.

Learn More

Gyratory Crusher Operation - Mineral Processing & Metallurgy

18/07/ · Gyratory Crusher Operation. Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a manner as to

Learn More

what is gyratory crusher gape

The Gyratory crushers are similar to cone crushers but they are three times greater than that of a jaw crusher of a similar gape; the gyratory has a Comparision between the crushers - Ranjit Gape length:- It is the width of the receiving opening of the crusher.

Learn More

PDF) A Gyratory Crusher Model and Impact Parameters

The development of a gyratory crusher model was achieved in the following three main stages: mathematical representation and coding of the

Learn More

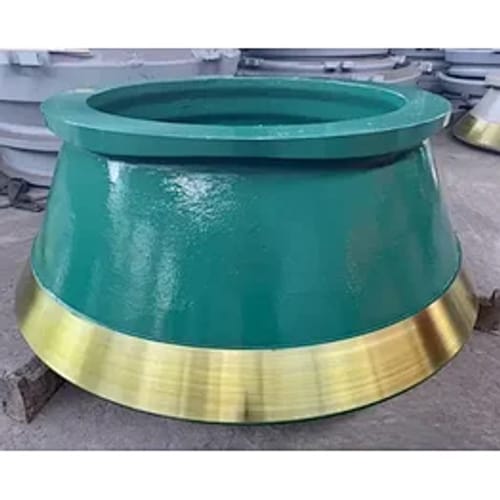

Gyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

The gyratory crusher is composed of transmission, frame, eccentric sleeve, mantle, concave segments, middle frame, beam, prime mover, oil cylinder, hydraulic pressure, pulley, electrical and dry, thin oil lubrication, and other parts. The motor drives the eccentric sleeve to rotate through the belt pulley and the bevel gear, and when the

Learn More

Gyratory Crusher - Mining Fundamentals

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat,

Learn More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the

Learn More

Operating Principle Of Gyratory Crusher

Gyratory crusher also named cone crusher is a large crushing machinery,The A gyratory crusher comprising:a bowl Primary Gyratory Crushers size,principle,operation in South The Mining Machine is custom designed to reduce your operating costs and increase your mine production by getting your mining, haulage and conveying systems to be

Learn More

Gyratory Crusher How It Works

Gyrating crusher broken cone of the cyclic movement of the cone cavity within the shell, squeeze the material, splitting and bending, rough chopped . What Is The Working Principle of Gyratory Crusher? - Crusher FAQ. When it comes to Replacement Gyratory Crusher Parts, Excel has been crushing the market for decades.

Learn More

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

Jaw gyratory crushers - design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn More

Difference Between Jaw Crusher and Gyratory Crusher - JXSC

The gyratory crusher is mainly used for coarse crushing various hard materials as primary crusher. But it is not suitable for crushing viscous materials. General the large-scale dressing mill uses gyratory crusher. Jaw crusher can crush high moisture, viscous ore, and not easily blocked. General the small-scale dressing mill and quarry mostly

Learn More

Gyratory crusher definition and meaning - Collins Dictionary

gyratory crusher in Chemical Engineering ; The · is a pot crusher with the rotating element set eccentric to the pot. ; The moving element of the · is a rotating

Learn More

fuctions of gyratory crusher

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and remove the eccentric assembly bushings and hydraulic piston. Read More

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Learn More