jaw plate material

JAW PLATES - Precision Casting

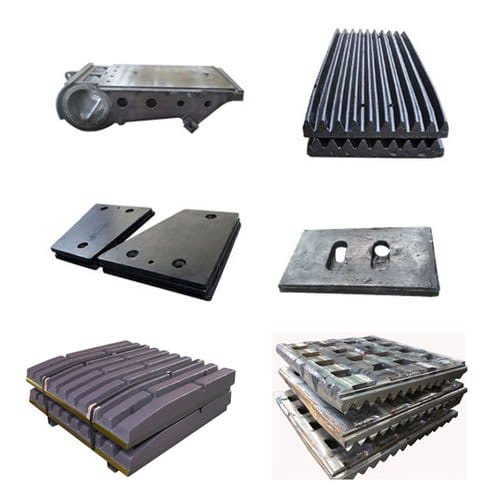

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher is achieved when the movable jaw die presses the feed against the fixed jaw die.

Learn More

Jaw Plates | Shanghai GDOO Mining Technology Ltd

Why Choose GDOO® Jaw Plates. ① We offer a variety tooth profiles and surface shapes; ② We offer different materials of jaw dies; ③ We produce more wear-resistant products; ④ We extend the service life of the jaw dies; ⑤ The fitting surfaces on all of our jaws are machine finished to ensure the best possible fit; ⑥ We provide more

Learn More

jaw plate material | gold mining machinery

What is the best material for crusher jaw plates? Dec 23, · Manganese Steel Jaw Plates Manganese steel is made by alloying steel, containing 0.8 to 1.25% carbon, with 11 to 15% manganese. Mangalloy is unique non-magnetic steel with extreme anti-wear properties. Know-how.

Learn More

jaw plate material | herbst agri crusher

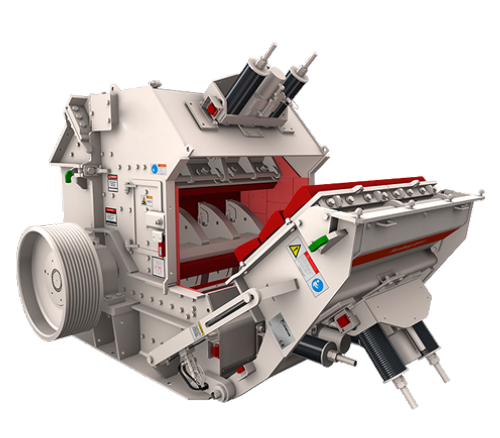

A jaw crusher's flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material. There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jaw.

Learn More

Resminer Stone Crusher Jaw Plates - Wear Resistance Supplier in China

Resminer stone crusher jaw plate is made of the special quality of manganese material. Our products are ISO certified. Competitive price in the market. Stone crusher jaw plate has long life span of service. High rate of corrosion resistance. Resminer Stone Crusher Jaw Plate Application Area

Learn More

Jaw Liners, Jaw Plate Material And Manufacturer | Quarrying

Jaw crusher liner material In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco’s products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer In the mining crushing and screening industry Most

Learn More

Crusher Jaw Plates For Popular Brands By Hunan JY Casting

The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed jaw plate and a 1 piece movable jaw plate. In order to rotate and exchange more easily, movable jaw plates also have 2 segments design and 3 segments design.

Learn More

Jaw Crusher Jaw Plate Material - China Manufacturers, Factory

We're hunting forward to your check out for joint development for Jaw Crusher Jaw Plate Material, Impact Crusher S, Gp200s Cone Wareparts, Mn13% Rolling Mortar Wall,Hti 1014 Scale Board. We are sincerely looking forward to cooperate with customers all over the world.

Learn More

Jaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale

Jaw Plate – Jaw Crusher Wear Parts. Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate

Learn More

Material of Mobile Jaw Crusher and Fixed Jaw Plate

When the eccentric shaft rotates, the movable jaw plate mainly bears the squeezing action of the material, while the fixed jaw plate mainly bears the sliding cutting action of the material. As a part with a high jaw wear rate, the choice of jaw plate material is related to the user's cost and benefit. 1. High manganese steel. High manganese

Learn More

4 Commonly Used Material Types for Jaw Plate

email protected] Jinhui Town, Fengxian District, Shanghai, China; Home; Products. Crusher Manganese Parts

Learn More

Jaw Plates - SHANVIM

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing

Learn More

How to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

Jaw plates are usually made of high manganese steel or medium-carbon-low-alloy cast steel, with different materials providing different advantages, depending on material and crusher types. ·High Manganese Steel High manganese steel jaw plates are wear-resistant and last longer but cost more to make.

Learn More

Jaw Plates: How to Choose the Right One for Different Types of Jaw

2022/7/20 · The jaw plate is an important part in the jaw crusher equipment, and its service life directly affects the whole jaw crusher equipment. Therefore, you must consider the hardness and toughness of the jaw plate when you want to choose a correct one. These jaw crusher plates are deliveried to Indonesia. If the hardness of the jaw plate is high

Learn More

Movable Jaw Plate Casting Manufacturers - EB Castworld

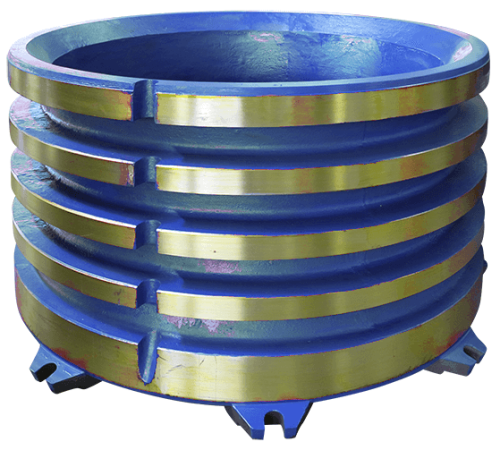

Movable Jaw Plate Casting Manufacturers Name: Movable Jaw Plate MOQ: 1 pieces Hardness: 48-62 HRC Elongation: 30 – 50% Delivery time: 7-30 days/ negotiation Size: Customize Advantage: Wear Resistant Manganese Contents: Mn13Cr2, Mn18Cr2

Learn More

What is the best material for crusher jaw plates?

12/23 · TIC Insert Jaw Plates. This material is developed by Qiming Machinery, it has improved our customer jaw plate by TIC (titanium carbide) insert. Compare with normal

Learn More

News - Crusher Jaw Plates Material Selection

Compare with normal manganese jaw crusher liners, our TIC insert wear parts span life can be 2-3 times. Based on our customer feedback, the more hard material to crush, the long span life.

Learn More

Jaw Crusher Plate Material - MGS Casting

3/25 · Jaw Crusher Plate Material. The heavy duty machines use in the first mechanical stage of comminution are mainly jaw crushers. The distinctive feature of t his class of crusher is

Learn More

Jaw Plate - Crusher Wear Spare Parts

Name: Jaw plate (movable plate, fixed plate), tooth plate, tooth plate Main Material: High manganese steel, manganese chromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), hard alloy. Casting Process: Sand modelling casting,Evanescent mode casting Application

Learn More

Jaw Plate - Toughing Crusher

Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek plate is

Learn More

Selection Of The Material Of Jaw Crusher Plate – Jaw Crusher

Therefore, large jaw crusher tooth plate is usually used ZGMn13Cr2 modified high manganese steel. For the jaw plate material should be selected high hardness materials to resist extrusion, micro-chisel failure, and also have sufficient toughness to resist the

Learn More