rubber mill liners

Grinding Mill Liners - 911 Metallurgist

Weight: Rubber weighs about 15% of an equivalent volume of steel. This means that a rubber liner system reduces the load on the mill structure

Learn More

Elastic polyurethane Mill liners - Eurogomma

Comparative test between premium quality Rubber liners and EUROGOMMA elastic polyurethane liners. Polyurethane case study 01. Polyurethane case study 02.

Learn More

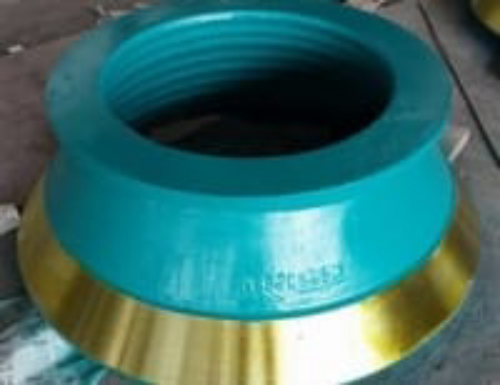

Rubber mill liners Factory | China Rubber mill liners

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner. Select right of your rubber liner supplier carefully will make sure your milling process runs at maximum capacity and availability.

Learn More

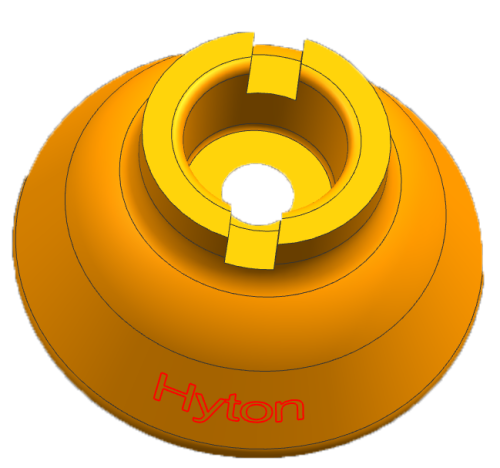

Mill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

Ball Mill Rubber Liner. The rubber linings produced by AGICO CEMENT can generally be divided into ball mill rubber linings, rod mill rubber linings, tube mill rubber linings, AG mill rubber

Learn More

Flexible Rubber Liner Manufacturer,Mill Liner Plate Exporter

KEDAR RUBBER PRODUCTS, We are finest Manufacturer,Supplier and Exporter of Flexible Rubber Liner and Mill Liner Plate from Ahmedabad, Gujarat, India.

Learn More

Rubber Mill Liners | FRASERS

24 Rubber Seals; 23 Tank Liners; 22 Mills; 22 Rubber Extrusions; 21 Rubber Sheeting; 21 Rubber Rings; 21 Metal Milling; 20 Rubber Extruded Gaskets; 20 Extruded Rubber; 19 Silicone Rubber Products; 18 Tapping & Milling Transfer Drilling Machines; 18 Spray-on liners; 18 Pulp & Paper Mill Equipment;

Learn More

Compare the Benefits of Steel VS Rubber/Poly-Met Mill Liners

24/07/ · Let’s compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills. The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball increases the cost benefit of using steel only mill liners. Looking at this chart, any time

Learn More

Ball Mill / SAG Mill Steel Shell Liners - Unicast Inc

Longer Wear Life: Unicast Rubber Liners are pressure molded to ensure highest density and engineered for maximum abrasion resistance. · Reduced Weight Lowers

Learn More

PDF The Selection and Design of Mill Liners - MillTrajPDF

Mill linings, Weir Rubber Engineering, Salt Lake City, UT 84126, United States of America . ABSTRACT . Dramatic shortcomings of mill liner designs, especially of large SAG mills, - such as rapid failure and even mill shell damage arising from impacting of the charge directly on the liner, and unsuitable

Learn More

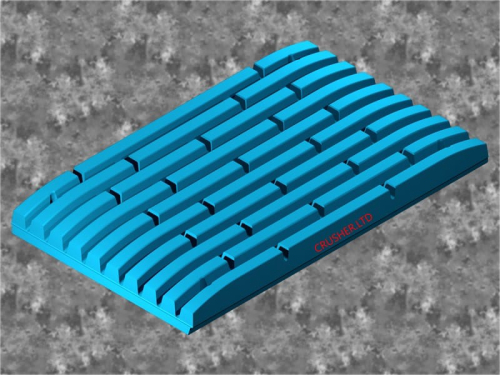

Rubber - Growth Steel

At Growth Rubber we know the importance of an optimized Mill Liner design. That is why we utilize the latest design and simulation software to ensure your Mill Liner System will provide optimal grinding performance at the lowest operational cost. Computer-Aided Design (CAD) 3D DEM Simulation. 3D Laser Scanning.

Learn More

Vulco® Mill Lining Systems | Weir Group

Weighing 35-40% less than steel, rubber and metal cap liners are faster and safer to install; Rubber liners significantly reduce the generated and transmitted sound level associated with grinding; Custom-designed to deliver similar service life for high- and low-wear zones of the mill, achieving a lower Total Ownership Cost (TOC) for your circuit

Learn More

Jiangxi Naipu Mining Machinery Co., Ltd. - Slurry Pump, Rubber Mill Liner

Jiangxi Naipu Mining Machinery and New Materials CO., LTD is a high-tech enterprise, manufacturing large-sized mining equipment, slurry pumps and rubber spares. With its headquarter located in Shangrao Economic Development Zone, Jiangxi, it runs a modernized and garden-like factory with a footprint of 35 thousand square meters, owns a 300

Learn More

Rubber Liners - Polycorp

Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26 feet in diameter. We have supplied Rubber Liners for more

Learn More

Rubber Mill Liners Market 2022 : Market Share, Top manufacturers Entry

The Rubber Mill Liners market revenue was Million USD in , grew to Million USD in , and will reach Million USD in 2026, with a CAGR of during -2026. Considering the influence of COVID-19 on the global Rubber Mill Liners market, this report analyzed the impact from both global and regional perspectives.

Learn More

Key considerations when selecting a mill lining system - The Weir Group

Rubber and composite mill liners are increasing in popularity, with several advantages when compared to metal mill liners: Ease and speed of manufacture, with shorter lead times Customisable, with ability to optimise abrasion and wear resistance Outlast metal linings when designed and manufactured correctly

Learn More

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

19/05/ · The mainstream ball mill liners materials currently used in the market are alloy steel and rubber. Alloy steel mill liner is wear-resistant and impact-resistant. Alloy steel has good

Learn More

Trelleborg Rubber Mill Liners - Trelleborg.com.au - Yumpu

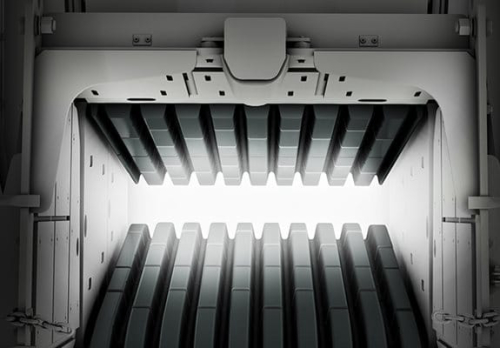

liner designs. Product Range. Trelleborg has a wide range of. Rubber lifter bars and plates for. Ball Mills, Rod Mills and Drum. Scrubbers.

Learn More

Mill Lining Systems | FluidHandling - Trelleborg

Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers. Our MILLTOUGH® EXTREME composite lifter bar is

Learn More

Rubber Liners Factory | China Rubber Liners Manufacturers and

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner. Select right of your rubber liner supplier carefully will make sure your milling process runs at maximum capacity and availability.

Learn More

Mill linings from rubber and steel - Outotec

Outotec's Skega Poly-Met™ mill linings combine the most desirable properties of rubber and steel to maximum advantage. This combination allows the use of more wear-resistant

Learn More

Selection and Design of Ball Mill Liners

The mainstream ball mill liners materials currently used in the market are alloy steel and rubber. Alloy steel mill liner is wear-resistant

Learn More