grinding mill liners

Grinding Mill Liners - EB Castworld % Ball Mill Liner % Grinding Mill

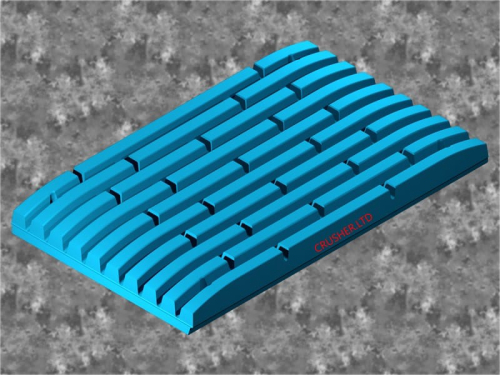

Grinding Mill Liners. Application: Grinding Mill Liners. Hardness: ≥HRC58. Impact value: ≥5J. Material Group: High Cr White Iron: BTMCr15Mo, BTMCr20Mo, BTMCr26Mo. Service Life: 1st Chamber: about 2 years; 2nd Chamber: about 4 years. Process: quenching & tempering treatment to achieve higher hardness and ideal impact value.

Learn More

Selection and Design of Ball Mill Liners

According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedge-shaped, corrugated, flat-convex

Learn More

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

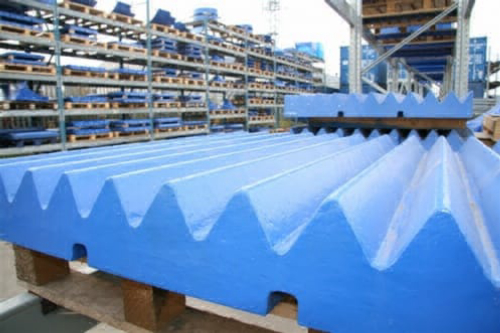

The mill liner is installed inside the ball mill barrel, separating the grinding media from the barrel, effectively buffering the direct impact of the grinding media on the barrel. Therefore, the barrel is protected, and the service life of the barrel and the entire ball mill equipment is prolonged.

Learn More

Mill Liner Solutions - Bradken

Grinding Mill Solutions Bradken is a leader in the design, manufacture and supply of mill liners for primary and secondary applications in the global mineral processing and quarrying industries. Mill Liner Solutions Bradken is a leading supplier of high quality Mill Liner Systems to suit AG/SAG, Ball and Rod Mills.

Learn More

New steel High-Chrome White Iron grinding mill liners

New "Steel" high-chrome white iron grinding mill liners. - For rod and ball mills. - Shell and head liners available. - Custom manufacture in North America.

Learn More

Rubber mill liners - Pioneering rubber mill linings - Outotec

Outotec rubber mill liners are tailor-made and developed in close collaboration with our customers. Being the pioneer, Outotec rubber mill linings are designed and produced based on the world's largest bank of know-how and experience. As a result, they last longer and your mill availability increases. Benefits Improved health and safety

Learn More

Resminer Mill Liner - Expert Manufacturer in China - Ware

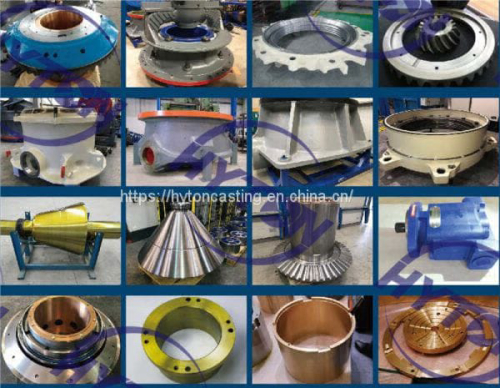

Resminer is a great choice if you want first-class quality mill liner and wear-resistant products. Our company is very expert in producing high features of grinding media and wear resistant’s including mill liner. We have grinding balls, grinding cylpebs, crusher parts, liner plate, toggle plate, Etc.

Learn More

Selection and design of mill liners - ResearchGate

Liners protect the mill shell from wear and transfer energy to the grinding charge. A careful balance is required to optimise these conflicting

Learn More

Best 30 Concrete Grinding in Hillsboro, OR with Reviews - YP.com

Concrete Grinding in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for the best Concrete Breaking, Cutting & Sawing in Hillsboro, OR.

Learn More

FC Mill Liners, Inc

easiest and most reliable supply of custom mill liners, period. produce application-specific mill liners that optimize grinding performance and provide

Learn More

MILL LINERS - COMESA

Grinding mill liners can be manufactured in various materials and designs. · There are other liner profiles. · In the case of rod mills, the

Learn More

Mill liners - The Weir Group

Our mill lining systems offer exceptional life and reliability in the most difficult grinding applications. Mill liners. Optimising grinding mill performance.

Learn More

China Grinding Mill Liners Factory and Manufacturers - H&G

grinding mill liners - Manufacturers, Suppliers, Factory from China, "Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for grinding mill liners, reline , L2C Mill liner , ball mill , Check Plate .

Learn More

ball mill liner - Magotteaux

These liners are efficient energy wise and make for low grinding media consumption. They can be assessed continuously via profile studies and the design can be

Learn More

Five tips on mill liners to improve grinding profitability 2/2

4. Optimized grinding mill liner design. A mill lining should be optimized by design in order to minimize problems, utilize the mill's capacity

Learn More

Semi-Autogenous Grinding (SAG) Mill Liner Supplier

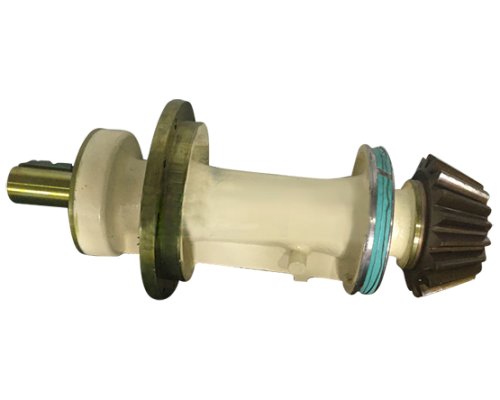

The heavy-duty Semi-Autogenous Grinding (SAG) Mill Liner are available in a range of widths, heights and in rubber or composite profiles. SAG Mill Liner are designed to be sacrificial linings to protect grinding mill shells and to enhance the movement of the charge for optimum throughput and grinding performance.

Learn More

Key considerations when selecting a mill lining system - The Weir Group

Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost. As materials technology and design technique has advanced, today many superior alternatives exist to metal linings.

Learn More

Shell Liners | Crusher and Mill Liners | CITIC HIC

CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wear-resistant castings. At the production base, we can produce a variety of wear liners for crushers, grinding mills and vertical stirred mills. Through from casting process design, mold making, smelting & casting, heat treatment, quality inspection, to packaging

Learn More

Grinding Mill Liners- An Overview

Grinding Mill Liners- An Overview · Solid liners · These are single units with integral lifters and fewer pieces but the downside is a higher

Learn More

Better Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For

Mill Liners for sale, Quality Better Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For Grinding Cement on sale of Zhengzhou Qianyue Mill Liners Co., Ltd. from China.

Learn More

Five tips on mill liners to improve grinding profitability 1/2

If the lining is transmitting the energy from the rotating mill to the charge, the grinding media is doing the actual grinding work. Breaking rock of a certain size and with certain properties requires a certain energy - and that determines the top media size. To get the final finer product, smaller sizes of media are required.

Learn More