cone crusher lubrication oil

Lubrication From Cone Crusher

Lubrication System for simons Cone Crusher. simons cone crusher is a common crusher which is widely used in mining industry. It adopts light oil lubrication system. lubrication plant from cone crusher pdf - CGM crusher quarry

Learn More

Cone Crusher MP1250 - Mobil

Cone Crusher MP1250 · Hydraulic-Hydraulic Power Unit · Frame · Lube System-Main Reservoir · Gear-Drive · Grease Points · Drive Components-Coupling · Bearing · Privacy

Learn More

CH860i & CH865i CONNECTED CONE CRUSHER

capacity technologically advanced, mid-range cone crushers crusher lubrication system for Oil flow. Oil pressure. Oil tank temperature. Oil level.

Learn More

Crusher Lubrication System Operation & Maintenance

18/07/ · For easy of Operation & Maintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level,

Learn More

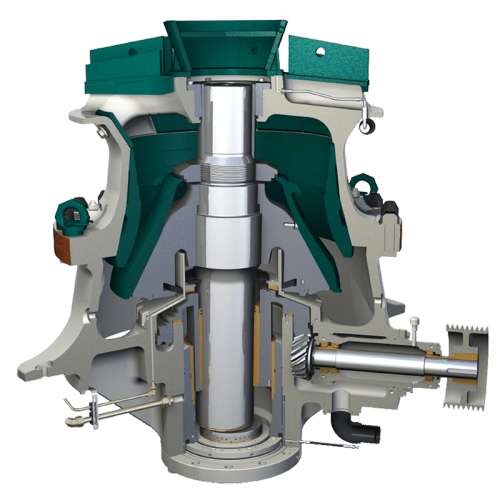

Cone Crusher Parts - Mineral Processing & Metallurgy

19/02/ · The lubricant is sealed in with a garter type oil seal. Bearings can be lubricated from outside the topshell on the 51, 60 and 84-in. crushers through oil holes in spider caps of the four smaller sizes. Cone Crusher MAINSHAFT. The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit.

Learn More

Notes of Cone Crusher Lubrication System - Machinery

1) The lubricating oil goes into the cone crusher by two paths. One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole lubricating big and small gear, and then the oil will return from the bottom oil returning

Learn More

Crusher Lubricant™ ISO 220 - Products - D-A Lubricant Company

Crusher Lubricant™ ISO 220. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings

Learn More

Oil Lubrication And Filtration System For Cone crusher I

11/06/ · Lubrication oil circuit pushes oil through the crusher bearings. During the operation of the stone crushing, heavy dust produces and enters in to the lubrica

Learn More

Notes of Cone Crusher Lubrication System

1) The lubricating oil goes into the cone crusher by two paths. One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole lubricating big and small gear, and then the oil will return from the bottom oil returning

Learn More

How to do the lubrication of the cone crusher-Jiaozuo zhongxin heavy

The cone crusher adopts thin oil circulation lubrication. It has two kinds of lubrication systems: one is the oil pump driven by the power of the drive shaft, called the integral lubrication system; the other is the lubrication system driven by the oil pump alone. Most crushers are equipped with The lubrication system driven by the oil pump alone.

Learn More

Oil Lubrication Services in Hillsboro, OR

Oil Lubrication Services in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for the best Lubricating Service in Hillsboro, OR. Auto Body Shops Auto Glass Repair Auto Parts Auto Repair Car Detailing Oil Change Roadside Assistance Tire Shops Towing Window Tinting. beauty. Barber Shops Beauty Salons Beauty Supplies

Learn More

What are the factors that affect the lubrication of the cone crusher

24/02/ · Secondly, the speed level. Cone crushing equipment, the faster the rotation, the more difficult between the rollers into the lubricating oil, which will cause poor lubrication, while high-speed operation of the oil is easy to agglomerate thicker. Therefore, the need to use low viscosity lubricants, low-speed need high viscosity lubricants.

Learn More

Cone Crusher Lube Systems | Crusher Mills, Cone Crusher, Jaw

Lubrication Oil Cone Crusher, Svedala – Offline Oil Lubrication Oil Cone Crusher, Svedala ASIN5031-UK Mining Crushers 12.06. THE SYSTEM Cone crusher H6000 Mark:

Learn More

Hillsboro - Jiffy Lube - Oil Change, Lubrication - 507 Se 10th Ave

About Jiffy Lube: Jiffy Lube - Hillsboro is located at 507 Se 10th Ave in Hillsboro, OR - Washington County and is a business listed in the categories Oil Change & Lubrication, Mobile Automobile Services, Auto Repair, Automobile Repair Shops, Auto Tune Up Lubrication & Oil Services, General Automotive Repair Shops, Automotive Repair Shops General, Nec, Auto Lubricating & Oil Services and Auto

Learn More

cone crusher lubrication system

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn More

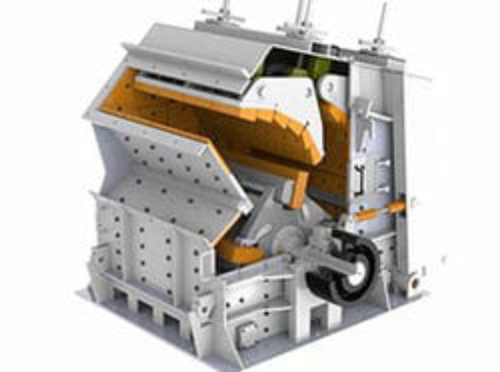

Re-Minder-Lubrication for SJ Jaw Crusher

Lubrication is very important for the equipment maintenance, what's the perfect way to add lubricant oil to Jaw Crusher?

Learn More

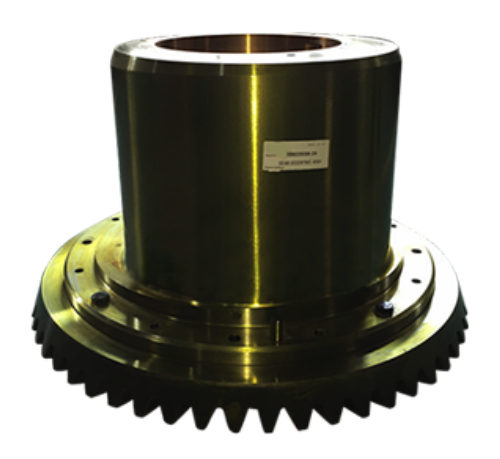

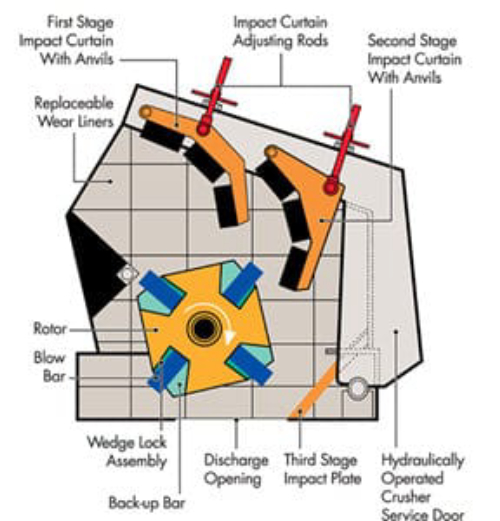

Cone Crusher Lube Systems | Crusher Mills, Cone Crusher, Jaw Crushers

The lubrication station is composed of the fuel tank, fuel pumps, filter (binoculars mesh oil filters and magnetic filter), tube cooler and instrumentation, piping Lubrication system of cone crusher | Gold Crusher Large feeding hole. The two top-shell arms are protected against wear by robust liners of special alloy steel.

Learn More

Jaw Crusher Lubrication Knowledge Analysis | 2019-09-10

50 oil as the lubricating oil. 2, the way of lubrication. Since the large and medium jaw crusher bearings and the eccentric shaft are pressure

Learn More

Eliminate 3 out of 4 crusher shutdown, install CJC® Oil Filters

Contaminated oil lead to we components, resulting in unforseen breakdown. Clean Oil on CRUSHERS, , Sishen Iron Ore, South Africa

Learn More

Five steps to optimize crusher's lubrication system - Outotec

A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF (15~60ºC), although ideally in the range of 100~130ºF (38~54ºC). In addition, oil temperature should be monitored frequently throughout the shift.

Learn More

Proper crusher lubrication - Tip of the Week - Lube Talk - Mobil

Oils: As a general rule, operators should use extreme pressure fortified gear lubricants with a minimum viscosity of 22 cSt at the bearing operating temperature. This typically demands an AGMA 3 EP or 4 EP gear oil. The lube oil should operate in a range between 10 and 50 degrees Celsius.

Learn More