gyratory crusher uses

Gyratory Crusher Pro - thyssenkrupp Mining Technologies

Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of

Learn More

Gyratory Crusher Explained - saVRee

Purpose of Crushers A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is

Learn More

Gyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

ThyssenKrupp Gyratory Crushers – Free download as PDF File (.pdf), text file (.txt) or read online for free. US Patent # 4,779,808. Gyratory crusher – Patents.com. A gyratory crusher of the type including a frame with a bowl mounted on the frame and a head cooperable with the bowl in crushing operations. The head is rotatably .

Learn More

Gyratory Crusher | Jaw Crusher Manufacturer | CITIC HIC

Our crushers have been exported to a number of countries such as Sweden and Brazil, and widely used in coarse crushing operations of iron ores, copper ores, gold ores and molybdenum ores. Numerous projects that we have successfully executed are the evidence of our ability to provide safe, reliable, energy-saving and high-efficiency crushing

Learn More

Crushers - All crusher types for your reduction needs - Outotec

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers - optimized for any size reduction need. Offering

Learn More

New head nut system for gyratory crushers - Mining Magazine

9/7 · Technofast Industries, a global hydraulic fastening company, has developed the EziTite Hydraulic HeadNut system which makes changing-out head nuts on gyratory crushers used in the mining and quarrying industries a far swifter and safer operation. Head nuts are used to retain the inner mantle of gyratory crushers. Processing > Comminution.

Learn More

What is a Gyratory Crusher | Quarrying & Aggregates

The crushing process of the gyratory crusher is to rotate one circle along the annular crushing cavity, and it can work continuously at 360°, while the main shaft of the jaw crusher rotates

Learn More

Used Gyratory Crushers for sale. Allis-Chalmers equipment & more | Machinio

Gyratory Crusher - Traylor 1000 TPH Primary Gyratory Crusher USED 1000 TPH Primary Gyratory Crushing Plant Item #1 - Fuller-Traylor Model 42-70 Type TCB Gyratory Crusher with cast steel two piece mainframe, 400 h.p. - 4,000 volt electric motor, direct shaft drive, hydraulic su

Learn More

Gyratory Crushers - Sandrock Mining

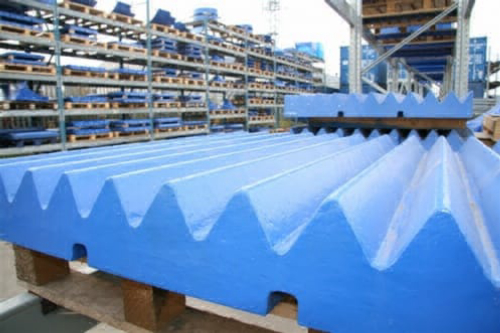

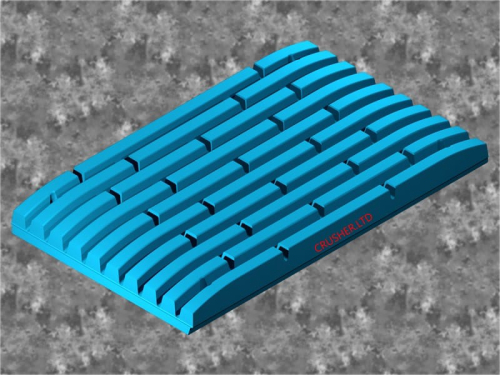

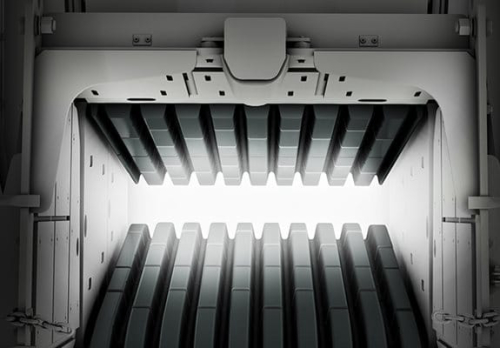

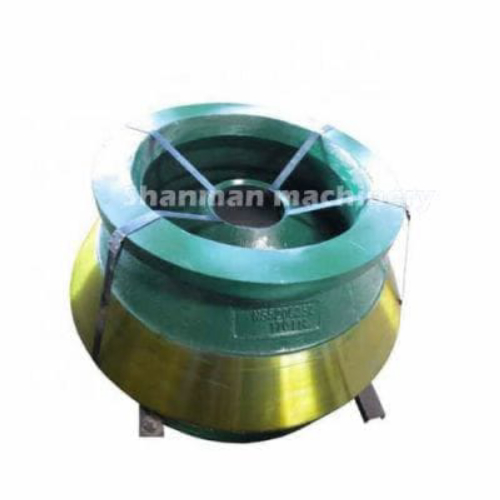

Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft

Learn More

Gyratory crushers - Industrial Solutions CIS

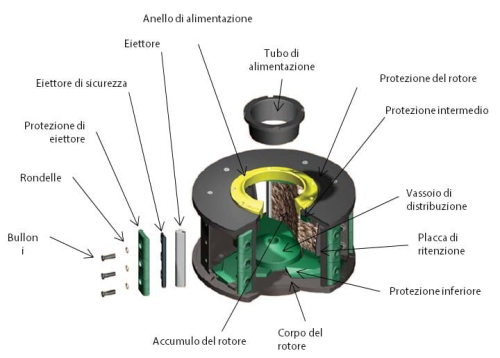

The use of a cyclo-palloid spiral bevel gear set allows the installation of higher-capacity drive motors if required. A pre-pressurized hydraulic system (

Learn More

en/gyratory crusher in dolomite crushing.md at main - GitHub

Cone crushers are the choice for use in medium hard to hard and abrasive natural stone as well as for raw material preparation in mining applications.The cone

Learn More

Gyratory VS Jaw Crushers: Advantages

2/28 · Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the

Learn More

The difference between a gyratory crusher and a

The gyratory crusher can perform continuous crushing operations, so productivity is relatively high. In addition, the crusher works more

Learn More

Use Of Gyratory Crusher In Industry | Crusher Mills, Cone Crusher, Jaw Crushers

Development of Rock Crusher Backing Products for the Mining This customer needed the materials for use in cone and gyratory crushers. Industry for Use: Mining and Quarry : Turn Around Time: 90 Days : Delivery Location: USA :

Learn More

Crushers and Their Types - IspatGuru

Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher

Learn More

gyratory crusher application and uses examples

Gyratory crushers gyratory crusher is generally used as a primary crusher. the crusher is popular due to its high throughput capacity and the large sized opening. the crusher is well suited for handling direct feed from hauldump trucks. the gyratory crusher is mainly used in rock that is abrasive andor has high compressive strength.

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of bulk materials mainly in ore mines and in the natural rock industry. Applications Large ore mines Limestone and cement industries Open pit and underground mining Aggregates industry Key advantages

Learn More

Gyratory and Cone Crusher - ScienceDirect

Figure 5.1 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines. Variations in the design of the breaking head and the mantle have been adopted by different manufacturers. Such variations are adopted from studies on stress distributions of component parts endured during the crushing operation.

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of

Learn More

Used Gyratory-crushers For Sale

Buy Used Gyratory Crushers. 10 Items Available Filter By Manufacturer. Sorty By UNUSED (Fuller-Traylor) 63" x 90" NT Gyratory Crusher with 600 kW (816 HP) Motor. Inventory ID: 3C-GM01. UNUSED (Fuller-Traylor) 63" x 90" NT Gyratory Crusher with 600 kW (816 HP) Motor

Learn More

Crushing 101 – Different types of crushers for distinctive needs

12/17 · Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Learn More