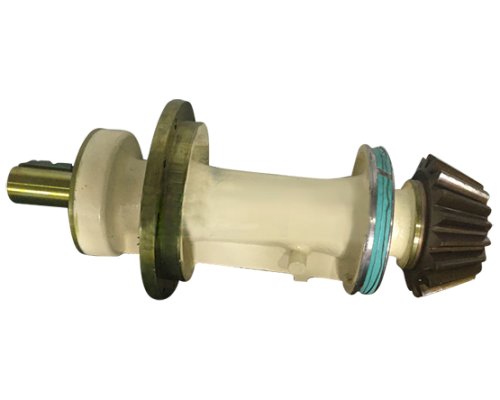

ball mill liner material

Rubber Ball Mill Liner - Strudex Mining

The ball mill liners' material and shape are different base on requirements. When the grinding media contacts with different shapes of ball mill liners, the movement state will also change, thus enhancing the crushing effect on the material. This design of the mill liners effectively improves the grinding efficiency of the ball mill machine

Learn More

Ball Mills | Industry Grinder for Mineral Processing - JXSC Machine

Ball Mills 【Capacity】 0.2-90 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】0.075-0.4mm 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custom-made parts,

Learn More

Ball Mill Liner Design - Mineral Processing & Metallurgy

05/01/ · The liners are from 50 to 65 mm thick (2″ to 2.5″) with the waves from 60 to 75 mm (2.5″ to 3″) above the liners. The replaceable lifter bar design made of either metal or rubber in

Learn More

21 Factors You Must Know About Ball Mill Liner - Mining-pedia

Metal material (manganese steel, chromium steel) and rubber is the main materials that produce ball mill liner. At present,metal material ball mill liner is widely adopted in the domestic market, while the rubber liner is also used in the mine. There are three functions of ball mill liner:

Learn More

Ball Mill Liner Material Manufacture and Ball Mill Liner Material

Total 24 Products for Ball Mill Liner Material) OEM Grinding Machine Ball Mill Liners. Brand: TyCrusher Parts; Packaging: 1.Wooden case special for expo Supply Ability: 60000 Tons/Year;

Learn More

Quality Ball Mill Liners & Mill Liners Manufacturer

Wuxi Orient Anti-wear Co., Ltd. We are a specialized manufacturer of wear and heat resistant castings. Our main products are Mill Liners for Ball Mills,SAG Mills,AG Mills,Crusher Wear Parts and Grinding Media. 1. The Production 1T,1.5T,3T,5T,12T,15T Induction Electrical Furnace Heat Treatment Electrical Furnace Process.

Learn More

Ball mill liner - WALDUN

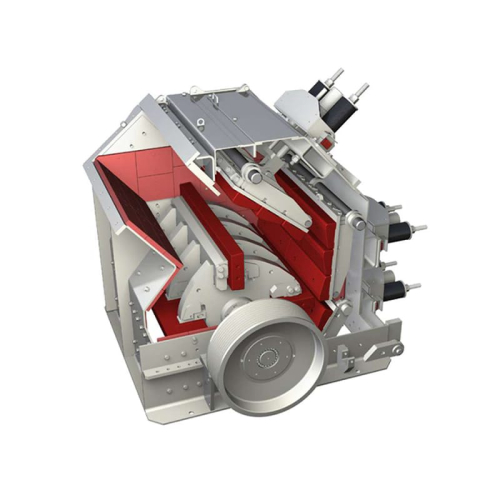

Ball mill liner. Ball mill liner is used to protect the cylinder so that the cylinder from the abrasive body and material direct impact and friction, but also use different forms of the liner to adjust the movement of the grinding body state, to enhance the grinding body of the material crushing effect, help improve the grinding efficiency of the mill, increase production, reduce metal

Learn More

Ball mill liner - Wear Parts For Industry | Qiming Casting

According to the price of the ball mill, the material of ball mill liners and the thickness of steel plate of the grinding body is required. Popular ball mills in China markets. There are some

Learn More

Ball mill liner - Zimaksan Co

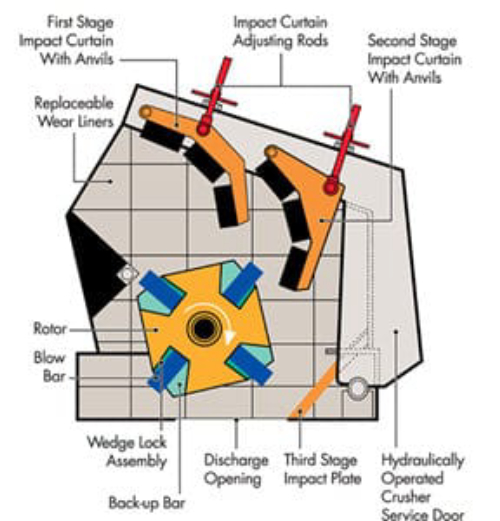

Ball mill liner . One of the most common types of grinding machines used today in many industries is a ball mill. This device works by using mass media balls made of solid materials, embedded in a compartment or container, in such a way that the material is crushed and powdered at the time of the cavity of the compartment on the material.

Learn More

Ball Mill Liners manufacturers & suppliers

China Ball Mill Liners manufacturers - Select 2022 high quality Ball Mill Liners products in best price from certified Chinese Wear Plate, Patio Paving Blocks suppliers, wholesalers and factory on Made-in-China.com. Variety Material Cement Industry Ball Mill Diaphragm Plate Crusher Liner Cone Crusher Liner. US$ 1 / Piece (FOB Price)

Learn More

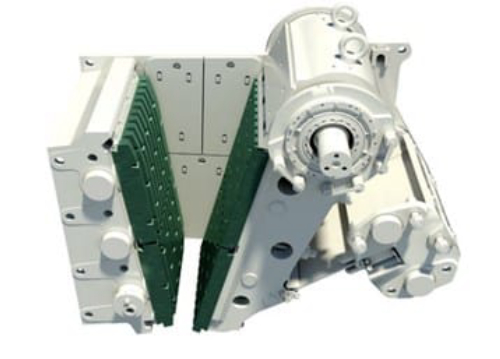

Ball Mill Linings | Multotec

Ball Mill Linings from Multotec provide optimum wear lining solutions for the toughest applications, ensuring optimum grinding and crushing efficiency. Our Ball Mill Lining designs

Learn More

Ball Mill Lining for Coal Mill - EB Castworld

Nickel Hard Ball Mill Lining and Liner Plates for Shot Blast Machines, Chutes, Clinker Silo, Port Machinery and Ball Mills This specification covers a group of white cast irons that have been alloyed to secure high resistance to abrasive wear in the applications of the mining, milling, earth-handling, and manufacturing industries.

Learn More

Ball Mill Liner ( Rubber , Polyurethane ) | Mill Rubber Linings Plate

Ball Mill Liner Plate Of Is Used To Protect The Cylinder From The Direct Impact And Friction Of The Grinding Body And Materials. At The Same Time, Different Liner Plates Can Be Used To Adjust The Movement State Of The Grinding Body, So As To Enhance The Grinding Effect Of The Grinding Body On The Materials, Improve The Grinding Efficiency Of

Learn More

liners crusherball liners mill -- earna

Ball Mill Liner Design Mineral Processing amp Metallurgy. Jan 05, The liners are from 50 to 65 mm thick (2″ to 2.5″) with the waves from 60 to 75 mm (2.5″ to 3″) above the liners.

Learn More

Wear-resistant mill liner, ball mill liner and SAG mill liner for

High manganese mill liner. Material: Mn13, Mn13Cr2, Chromium alloy steel, rare earth wear-resisting steel Process: lost mold Applicable machinery: ball mill, vertical mill, mill, mill, crusher Performance advantages: 1.Using modified high manganese steel and super high manganese steel, has enough impact toughness.

Learn More

Ball Mill Alloy Liner - EB Castworld

Ball Mill Alloy Liner. The ball mill liner is used to protect the barrel and protect the barrel from direct impact and friction of the grinding body and the material. At the same time, different forms of liner can also be used to adjust the movement state of the grinding body to enhance the grinding effect of the grinding body on the material. , Help to improve the grinding efficiency of the

Learn More

Steel Ball Mill Liners

In Φ2.2 x 6m ball mill, the capacity is 3.2mt per hour on 2μm∼10μm, which has achieved leading level at home and abroad. In 2000, we designed the first set of the boltless liners applied in a super fine powder vibrating mill in China. In 2003, we designed and manufactured ball mill liners used in the largest super fine powder ball mills

Learn More

High Density Polyethylene 40 mil| HDPE Liner/ Geomembrane

GPS HD 40 mil is a smooth, high quality, high density polyethylene (HDPE) geomembrane produced from specially formulated, polyethylene resin. This polyethylene resin is designed specifically for flexible geomembrane applications. It contains approximately 97.5% polyethylene, 2.5% carbon black and trace amounts of antioxidants and heat

Learn More

Ball Mill - an overview | ScienceDirect Topics

Ball mills are filled up to 40% with steel balls (with 30-80 mm diameter), which effectively grind the ore.The material that is to be ground fills the voids between the balls. The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fracture.

Learn More

Mill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

The mill liner is installed inside the ball mill barrel to protect the inner wall of the barrel from the impact of materials and grinding media (steel balls, steel sylpebs, steel rods, etc.) to avoid

Learn More

Ball Mill Maintenance & Installation Procedure

Mill SHELL Liner & HEAD Liners Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place. Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings.

Learn More