gyratory cone crusher

Cone Crushers | McLanahan

Features & Benefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Learn More

Top Service Gyratory Crusher TSUV

With low grade ore deposits requiring higher power and higher throughputs than ever before, you need a crusher that can take the impact - without compromising on efficiency. With more power and

Learn More

Torque Analysis of a Gyratory Crusher with the Discrete

A multibody dynamic and discrete element method was presented to analyze the performance of the GYP1200 inertia cone crusher, and it was contrasted with

Learn More

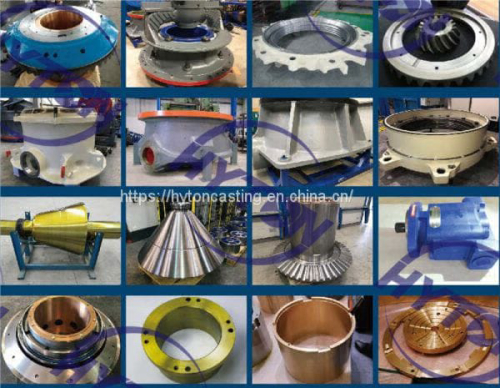

gyratory crusher mantle | spare copper-alloy parts for crusher crusher

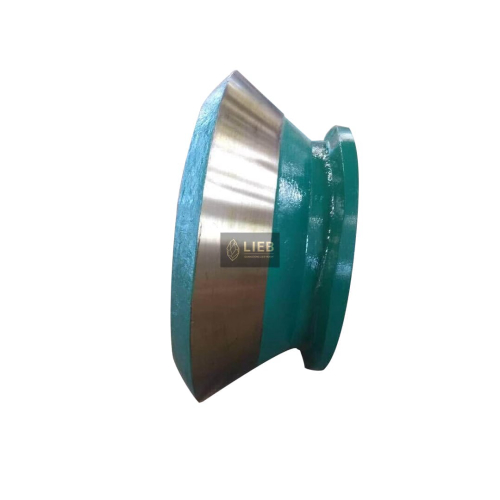

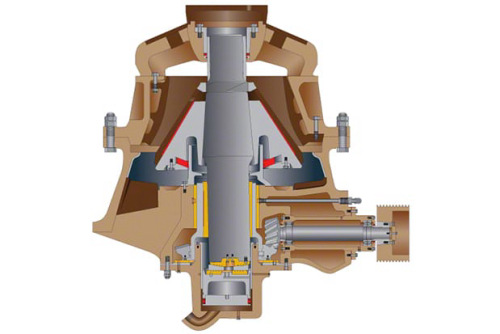

A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves. As the mantle gyrates within the crushing chamber, progressively approaching, and receding from, each element of the cone shaped inner surface, it creates compressive force, which fractures the

Learn More

Gyratory Cone Crusher Parts - Sandrock Mining

Applications: Calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic mineral flour, pulverized coal preparation ISO9001 Quality Assured Our comprehensive range of replacement crusher parts to suit primary gyratories are certified to meet the OEM specification.

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower

Learn More

Gyratory Cone Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher shape of two cones are steep, and can be fixed upright truncated cone is the cone, fixed cone is inverted truncated cone, which is mainly to increase - Fuller-Traylor gyratory crushers

Learn More

Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact

Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact Coal Grading Sieve Sand Making Cone Crusher Machine Parts , Find Complete Details about Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact Coal Grading Sieve Sand Making Cone Crusher Machine Parts,Gyratory Stone Gold Ore Perlite Diesel Engine Tin Aggregator Pulverizer Mill Cone Crusher Mining Machine Parts

Learn More

Gyratory crushers - thyssenkrupp

The design of our gyratory crushers and jaw gyratory crushers is based on over thyssenkrupp gyratory crushers in primary crushing is second to none.

Learn More

Gyratory Crusher Pro - thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally

Learn More

Gyratory Crusher manufacturers & suppliers

High Quality Gyratory Jaw Crusher Price Quotation for Crushers. US$ 13000-19000 / Set. (FOB Price). 1 Set (MOQ). Type :

Learn More

Crusher - Wikipedia

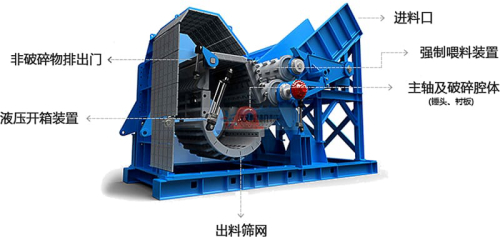

cone crusher can be divided into four types: compound cone crusher, spring cone crusher, hydraulic cone crusher and gyratory crusher.

Learn More

launch next generation “2 Series” gyratory cone crusher

Featuring the renowned CS430 gyratory cone crusher, it is able to accept a feed size up to 90% larger than current standard cones. This produces

Learn More

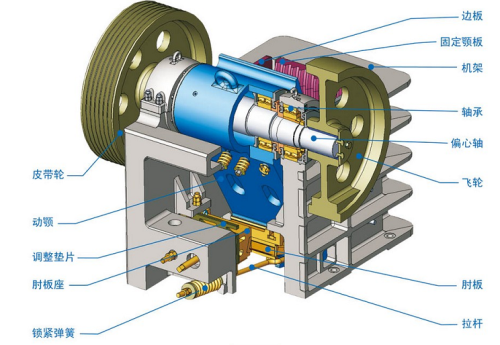

Cone Crusher Explained - saVRee

Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone crushers are more often used for 2nd, 3rd & 4th stage crushing steps (although not always).

Learn More

Cone crusher basics in 4 minutes — SRP

The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher. Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed.

Learn More

GYRATORY CONE CRUSHER, CRUSHING IRON ORE WITH NEW

viralvideos #viral #ironore # conecrusher #ironorecrushing #ironoreprocessing #ironoremining #ironore #kobelcogyratoryconecrusher #mantleshaft #liner

Learn More

High-Speed Gyratory Crushing --> Fine Cone Crushers

This 10″ reduction crusher, with its 40″ head, compares closely, in this respect, with the 20″ standard crusher, which has a 38″ head. Using straight-face concaves, the permissible minimum open side settings are 1.5″ for the former, and 3.5″ for the latter. With non-choking concaves these settings are, respectively, 1 1/8″ and 2 1/4″.

Learn More

China gyratory crusher - Alibaba

DUOLING GYRATORY CONE CRUSHER PRICE IN INDIA FOR SALE. Kunshan Duoling Heavy Machinery Technology Co., Ltd. US $29999-$999999 / set.

Learn More

Hard Iron Ore Pulverized by Gyratory Cone Crusher

ironoremining#kobelcogyratoryconecrusher#hardironore#ironoreprocessing #ironorecrushing #conecrusher #viral #viralvideos #ironoreprocessing # crusher

Learn More

Gyratory Crushers - SolidsWiki

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory cone crushers are

Learn More

GYRATORY CONE CRUSHER

SISCO' Gyramatic Hydraulic Roller Bearing Gyratory Crusher, which apply a unique hydraulic control system, are used in Primary, Secondary or Tertiary

Learn More