vibration analysis of a single toggle jaw crusher mechanism

fracture toughness based models for the prediction of power

single particle breakage analysis now is to further relate the fracture energy and Single toggle jaw crushers can range in speed from 200 rpm to 350.

Learn More

Analysis of the Single Toggle Jaw Crusher Force Transmission

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism. In order to obtain force transmission metrics that are characteristic of the structure of the mechanism, such influences as friction, dead weight, and inertia are considered to be extraneous and neglected.

Learn More

Research Article Analysis of the Single Toggle Jaw

is paper performs a static force analysis of the single toggle jaw crusher mechanism. As a result of this analysis, a characteristic force transmission ratio, which may be regar-ded as a

Learn More

Master Thesis in Mechanical Engineering - DiVA portal

of vibration, noise and dynamic forces which can be transferred to other parts matrix-single value decomposition (PSDTM-SVD), between jaw crusher foot.

Learn More

Analysis of the single toggle jaw crusher kinematics

Generally speaking, the aim of any kinematical analysis of a mechanism is to determine the output motion, given the input motion and the

Learn More

Method for adjustment of jaw crusher toggle block, and device

The objective of this invention is to provide a method to adjust the position of a jaw crusher toggle block, and a device used for said method;

Learn More

Optimum Design and Analysis of Swinging Jaw Plate of a

Optimum Design and Analysis of Swinging Jaw Plate of a Single Toggle Jaw Crusher Thesis Submitted in Partial Fulfillment of the Requirements for the Award

Learn More

JAW CRUSHERS VIBRATION ANALYSIS

Jan 01, · Analyzing the vibration parameters of gas-cleaning units operated in coal and mining industry of Kuzbass. Article. Jul 2021. P. B. Gerike. Boris Gerike. V. I. Klishin.

Learn More

Analysis Of Single Toggle Jaw Crusher

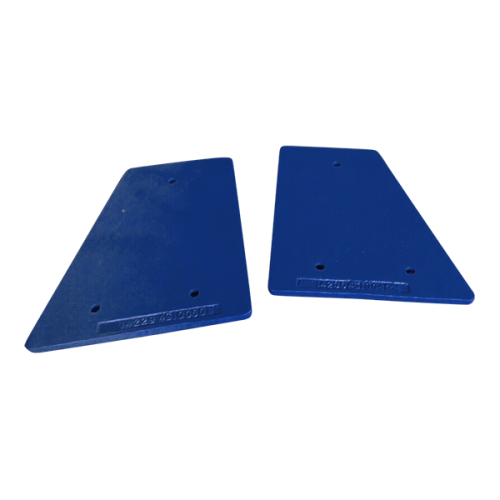

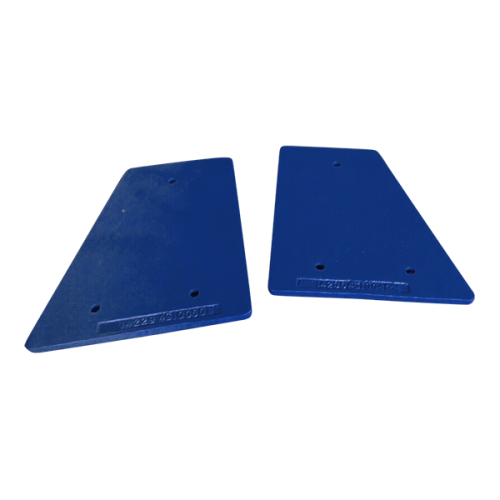

The frame consists of two side plates of rolled steel, plus hollow castings at front frame end and moving jaw which give a high,May 05, · – This paper aims to obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher.,The swing jaw drive mechanism of a single toggle jaw

Learn More

analysis of single toggle jaw crusher

May 05, The swing jaw drive mechanism of a single toggle jaw crusher is modelled as a planar crank and rocker mechanism with the swing jaw as the coupler link. Starting with the vector loop closure equation for the mechanism, equations of the position, velocity and acceleration of any given point in the swing jaw are obtained.

Learn More

Analysis of the Single Toggle Jaw Crusher Force ... - Hindawi

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of

Learn More

minyu crusher parts flow switch asm h4000 GP550 V-BELT ISO4184

Whether it's aggregates, mining, construction & demolition, recycling or road building our jaw, cone & impact crushers are ready for any job. I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine; Crawler Tracks; Integrated hydraulic folding stockpiling conveyors.

Learn More

development of a laboratory size single toggle jaw crusher for

Consequently, the objectives of this study are to design a 0.1 tonne/hr capacity single toggle jaw crusher; develop critical components for easy and timely

Learn More

Jaw Crusher Working Principle - 911 Metallurgist

The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of

Learn More

LT1100 CLAMP DIN3017-SA40-60-W1 | vibration analysis of a single toggle

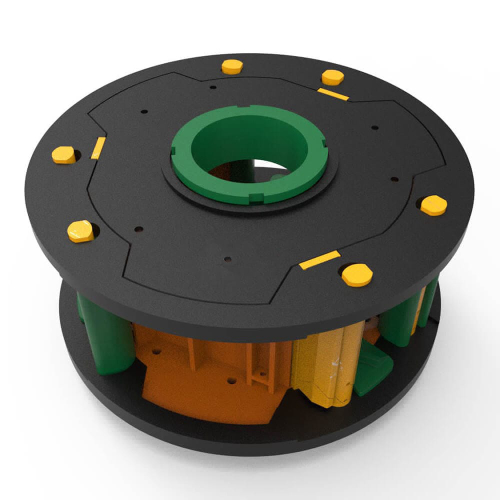

LT110 Jaw Plate Quarry Design 1P - Bogvik Daily shrink type outerhc84145.15007-351-997-026stud 2.000-4.5unc-3a x 10.25sg54743.94007-354-558-001pinionshaft armlnr right hand 75sg5474235.87007-354-558-002pinionshaft armlnr left hand 75sg5474224.98007-354-559-001narrow arm liner 75sg5474331.12007-445-912-001eccentric bushing 1.625 throw

Learn More

Design and Analysis of Swing Jaw Plates of Jaw Crusher

For a smooth reciprocating action of the moving jaws, heavy flywheels are used in both types of crushers. &the eccentric shaft. Single toggle jaw crusher,

Learn More

JAW CRUSHERS VIBRATION ANALYSIS - ResearchGate

Analyzing the vibration parameters of gas-cleaning units operated in coal and mining industry of Kuzbass. Article. Jul 2021. P. B. Gerike. Boris Gerike. V. I. Klishin.

Learn More

Jaw Crusher Working Principle - Mineral Processing

May 06, · A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar: the movable jaw has

Learn More

Research Article Analysis of the Single Toggle Jaw Crusher

is paper performs a static force analysis of the single toggle jaw crusher mechanism. As a result of this analysis, a characteristic force transmission ratio, which may be regar-ded as a mechanical advantage of the mechanism, is derived. is ratio can be used as a criterion for the comparison of di erent jaw crusher mechanism designs, with a view to

Learn More

Crushers - an overview | ScienceDirect Topics

The crushing force is doubled compared to single toggle crushers and it can crush very hard ores. The jaw crusher is reliable and robust and therefore quite

Learn More