clinker cooler for cement plant

Reliable, low-maintenance cement clinker coolers

Advanced clinker coolers for your cement plant · Rotary cooler for lithium processing · Heavy-duty Roll Breaker · ABC™ Cooler Inlet · Cross-Bar® Cooler · Grate for

Learn More

DE102014100378B3 - Clinker cooler and method for cooling clinker

In the production of cement clinker, the clinker used in a clinker cooler process heat, for example, used to generate electricity. For this purpose, 20 hot clinker is placed on a grate 11 of an

Learn More

Energy and Exergy Analysis of Clinker Cooler in the Cement Industry

The essential function of grate coolers is a waste heat recovery from hot clinker which leaves the rotary kiln. This paper presents an analysis of energy and exergy based on the clinker temperature

Learn More

Energetic and Exergetic Efficiencies of a Grate Cooler in an

clinkers coming out of rotary kilns. This work focuses on the thermal performance of the clinker cooling system in a cement production plant employing the

Learn More

How To Realize Heat Recycle In Clinker Production Plant

Heat Recycle Project for Clinker Rotary Kiln. In June , the 6MW waste heat generator set was put into operation, generating capacity of 80,000 to 100,000 kw per day. In order to further recovery of cement clinker production plant calcining heat loss of production, we analyzed the Φ 4 m by 60 m distribution characteristics of rotary kiln

Learn More

The polytrack® clinker cooler - innovative and sustainable

In the production of cement clinker, temperatures in the rotary kiln reach 1,300 to 1,400°C. In order to be able to grind the clinker into cement products, it has to be cooled to below 100°C. In more than 130 cement plants worldwide this task is performed by a cooling system developed by thyssenkrupp - the polytrack ®.

Learn More

polytrack - thyssenkrupp Polysius

polytrack® - the clinker cooler for cement industry and cement plants The polytrack® is the reliable clinker cooler of thyssenkrupp. The focal point of our

Learn More

Clinker Cooler - AGICO Cement Plant

The clinker cooler is mainly used to cool and transport the cement clinker. At the same time, cement cooler also provide hot-air for rotary kiln and calciner,

Learn More

clinker cement plant mill hzs120 ready mixed belt type concrete faqs

How does the Concrete mixing plant works. Concrete mixing plant is divided into four parts: gravel feed, powder (cement, fly ash, bulking agents, etc.) to feed, water and feed additives, transmission and storage stirred their workflow shown in Figure 1. , the mixer control system power, into the human - machine dialogue operation interface, system initialization process, including recipe

Learn More

White cement cooler - thyssenkrupp Industrial Solutions

Especially for the white cement production process, thyssenkrupp Industrial Solutions developed the twin cooler, consisting of rotary cooler, roll crusher

Learn More

Clinker Cooler, Cement Cooler, Grate Cooler | Clinker Production

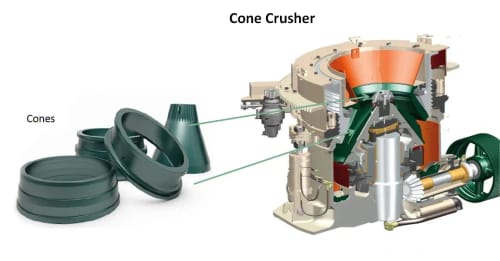

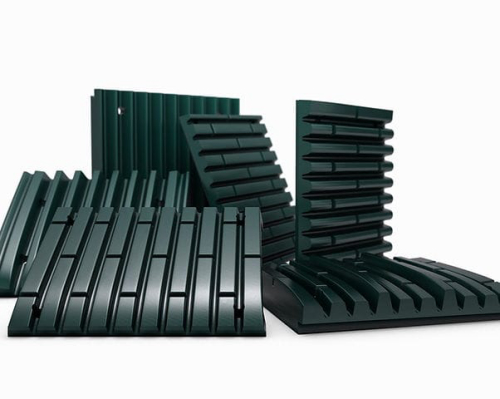

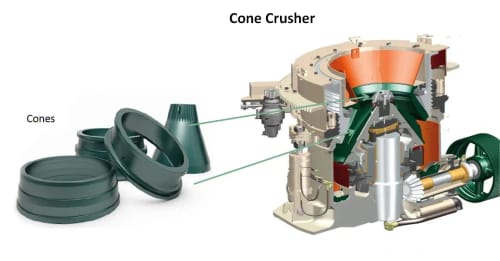

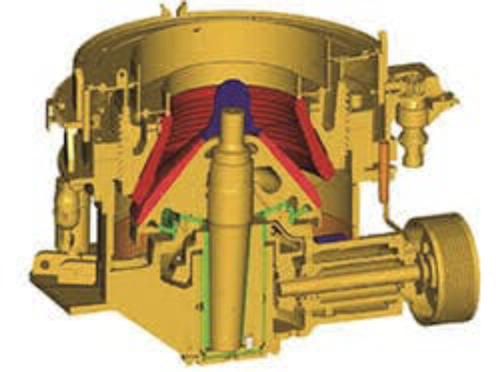

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used to cool and transport the cement clinker. At the same time, cement cooler also provide hot-air for rotary kiln and calciner, it is the main equipment of heat recovery for burning system.

Learn More

The impact of cooling water types on the cement clinker

The plant includes industrial processes related to the production of white cement. It is using Nile water at different processes such as cooling clinker in the

Learn More

Clinkerization - Cement Plant Optimization

Clinker can contain about 0.012 to 0.023 % cl. Liquid Phase (%) mainly consists of the aluminium, iron and magnesium oxides. However, alkalies and sulphates also contribute to liquid phase. The liquid phase plays an important role in coating formation and nodulisation. The liquid percentage at 1450 0 C can be estimated using the formula

Learn More

Clinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

As the supporting equipment of cement rotary kiln, clinker cooler (also called cement cooler) is a kind of heat exchange device that transfers heat from high-temperature clinker to low

Learn More

Clinker Cooler - Home

Clinker Cooler. 140 likes. Being kiln is the heart of Cement plant, Clinker cooler is the heart of the Kiln. Knowing about clinker cooler design is vital to make your plant green!

Learn More

Virtual-Lab of a Cement Clinker Cooler for Operator Training

Abstract. Plant operator training plays a fundamental role in improving the energy efficiency of the the cement manufacturing process and reducing CO2

Learn More

Method and plant for manufacturing cement clinker

A description is given of a method as well as a plant for manufacturing cement clinker by which method cement raw meal is preheated in a preheater (1), calcined in a calciner (3) comprising an upper end (3a) and a lower end (3b), burned into clinker in a kiln (5) and cooled in a subsequent clinker cooler (7).The invention is peculiar in that exhaust gases from the kiln (5) are introduced into

Learn More

Grate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

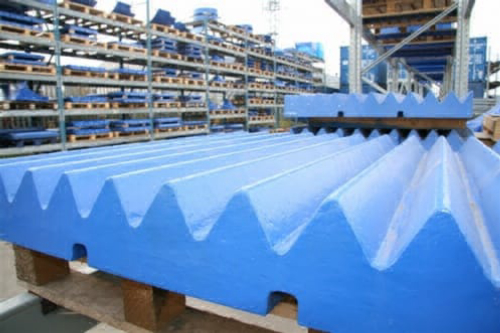

Grate cooler, as a quench type clinker cooler, is the important cement equipment in the clinker calcination system. Its main function is to cool and transport cement clinker. Meanwhile, provide hot air for cement rotary kiln and precalciner.

Learn More

Cement Production | Cement | Howden

Changshan South Cement, China benefitted from a cost-saving energy retrofit of its two clinker production lines with MC-2x39No30.5F raw mill circulation fans. Fan Retrofit at St Marys Cement Howden team retrofit an existing Induced Draft (ID) fan resulting in annual savings of $200,000.

Learn More

PDF Performance Evaluation of A Grate Cooler in A Cement Manufacturing ...PDF

The specific water flow [kg/kg. clinker] = Net Water Flow [kg/hr] / Total Clinker [kg/hr] 3.1.2 Cooler Output The clinker output from the cooler is expected to be 1 kg provided no loss in mass. 3.1.2.1 Excess Air The cooler excess air was found by measuring the temperature and static pressure at cooler at cooler ESP stack.

Learn More

Clinker Cooler System In Cement Plant (Kiln System Part 6) _ English

Clinker Cooler System In Cement Plant (Kiln System Part 6) _ English Version, the equipment used to cooling the clinker coming out of the Rotary Kiln.Cooler

Learn More