grate cooler design

PDF Pan Conveyors - AumundPDF

between cooler and clinker stock especially for applications with grate coolers. The design allows the Pan Conveyor to be arranged underneath the whole cooler length and to collect the fines from the dust collecting hoppers same as the clinker from the crusher. Installed underneath the clinker stock in combination

Learn More

Grate Coolers Modern Technology For Cement industry

The grate type cooler is the most suitable cooler for pre-calciner kiln and for kilns with a high outputs Nowadays grate cooler are designed for large kiln capacities up to 10000 t/d It's based on

Learn More

Optimization Design of the Grate Cooler Based on the Power Flow

In recent years, a large number of methodologies for the optimal design and control of grate cooler have been developed, which can be categorized into two broad types. One is to propose mathematical models of the clinker cooling process, the theoretical foundations of most of which are based on convection heat transfer principle [8] and porous

Learn More

How To Prolong The Service Life Of Grate Cooler? | AGICO CEMENT

Sep 16, · The grate cooler has four generations since it was created. The first generation is grate cooler with a thin layer, it has lower capacity; the second generation is grate cooler with a thick layer, there is a relative increase in its production, promote the cooling efficiency of grate cooler; the third generation is Air beam grate cooler, the cooling efficiency improve a lot

Learn More

Multi-objective optimization design of air distribution of grate cooler

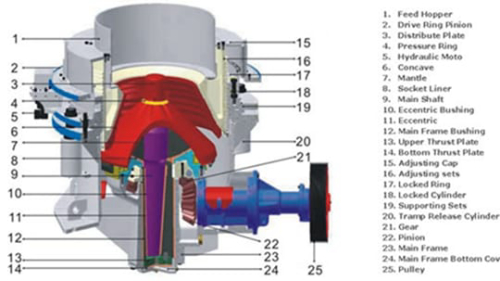

Grate cooler plays a very important role in cement production line whose main functions are quenching high temperature clinker and redistributing the exhaust hot air as shown in Fig. 1 (a). Increasing clinker cooling efficiency has great effects on decreasing power consumption of cooling fans and improving quality of clinker.

Learn More

Heat Exchange Modeling of a Grate Clinker Cooler and

The concept of the exergy analysis is applied to a grate cooler of a cement production facility. design of the cooling process.

Learn More

Grate Cooler in Cement Plant

Grate Cooler Working Principle The hot clinker discharged from the rotary kiln falls on the grate bed. Under the push of reciprocating grate plate, the hot

Learn More

Optimization Design of the Grate Cooler Based on the Power Flow Method

As an important process during the cement production, grate cooler plays significance roles on clinker cooling and waste heat recovery. In this paper, we measured experimentally the heat balance of the grate cooler, which provided initial operating parameters for optimization.

Learn More

performance evaluation of a grate cooler in a cement ... - IJSEAS

This study revealed that the grate cooler efficiency estimated through heat consumption balances conformed to the designed standard.

Learn More

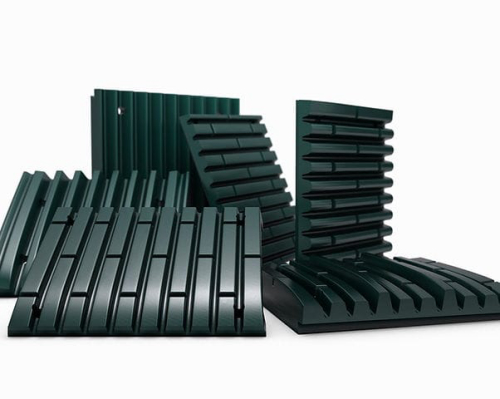

Clinker cooler | Magotteaux

Reciprocating clinker coolers represent the best option available on the market. Magotteaux patented Bar Grate Design provides optimal cooling with the following features: Custom-built air distribution system; Grates and clinker are cooled; Heavy-duty resistance against distortion; Magotteaux Mining / Cement / Aggregates / Recycling Hammers

Learn More

Cooler Options | World Cement

Ask any cement plant manager about the clinker cooler in his plant, The new erection concept, which utilises a modular design,

Learn More

IKN Grate System

Cool Down IKN Pendulum Cooler® and KIDS® are designed to reach low clinker outlet temperatures at high recuperation rates. IKN Products. Cooler inside. IKN

Learn More

Maintenance Of Under Grate Pressure in Grate Coolers

A design of Internal Model Control based PID controller for maintaining the under grate pressure of a grate cooler used in cement plants is presented in

Learn More

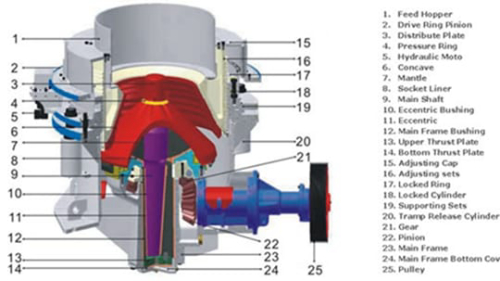

Grate Cooler – Clinker Cooler | AGICO Grate Cooler In Cement Plant

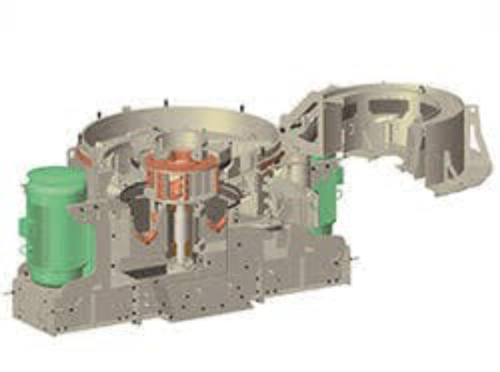

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan.

Learn More

EP0525380A1 - Grate cooler - Google Patents

The invention relates to a grate cooler, in which the drive device is surrounded by a drive housing, the inner space of which is sealed in an airtight manner in relation to the atmosphere, but on the other hand has a pressure-equalisation connection to the inner space of the cooler housing. Such a grate cooler is characterised by considerably reduced expenditure for sealing the cooler

Learn More

Maintenance Of Under Grate Pressure in Grate ... - ijareeie

ABSTRACT: A design of Internal Model Control based PID controller for maintaining the under grate pressure of a grate cooler used in cement plants is

Learn More

KHD PSC² Cooler

Grate coolers are still essential to the cement industry in many countries. With our revised and improved Pyrostep² grate cooler design, we offer cement prod

Learn More

Grate Cooler Design

Grate Cooler Design GRATE COOLER PABRIK SEMEN Gambaran Umum Dalam Proses pembuatan semen, klinker yang sudah diproses dari awal sampai dipan.

Learn More

Multi-objective optimization design of cement grate cooler control

As a complicated and slow control process, there are several control objectives of the grate cooler, which are determined by design parameters. To compute the time delay of the design parameters automatically, we propose an improved long short-term memory with adaptive computation time (ACT-LSTM) model for objective prediction.

Learn More

Grate Kiln System

Oct 14, · Initial GRATE-KILN plants were designed with no heat recuperation systems and typically consisted of a two pass, downdraft drying and downdraft preheat grate cycle. A preheat bypass system was installed to complement the preheat off-gas supply so that these two streams delivered the required downdraft drying heat supply.

Learn More