jaw crusher plate

Crusher Jaw Plate Manufacturers in Bangalore - Justdial

18 Crusher Jaw Plate Manufacturers in Bangalore. Find ✓Bearing Dealers, ✓Conveyor Belt Dealers, ✓Barcode Scanner Dealers, ✓V Belt Dealers,

Learn More

What are the Materials of the Jaw Crusher Plates and Which is

In recent years, high-chromium cast iron is used for inlay casting or bonding on the high-manganese steel jaw plate to form a composite jaw plate, which has a relative wear resistance

Learn More

jaw plate crusher parts, China jaw plate crusher parts, jaw plate

China jaw plate crusher parts catalog and jaw plate crusher parts manufacturer directory. Trade platform for China jaw plate crusher parts manufacturers and global jaw plate crusher parts buyers provided by

Learn More

Jaw Plates - Emerald Parts

actively offers jaw dies, cheek plates, and hardware for the continued replacement of Powerscreen, Cedarapids, Finlay, Evoquip, and Extec jaw crushers.

Learn More

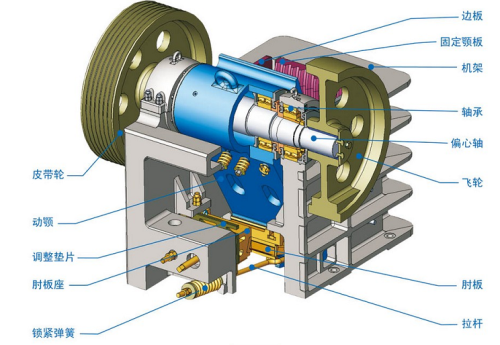

Jaw Crusher Toggle Plates vs. Hydraulic Toggle Relief Systems

Apr 10, · A toggle plate basically operates like a fuse. If any material enters a jaw crusher that cannot be crushed, whether due to its size or composition, the toggle plate is meant to break, relaxing the moving jaw open to allow for the uncrushable material to fall through or be removed manually. Traditionally, jaw crusher toggle plates are made of

Learn More

Jaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

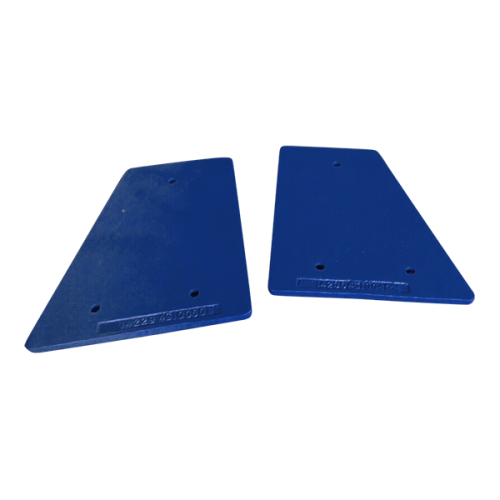

Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate according to the customer’s model

Learn More

Crusher Jaw Plates For Popular Brands By Hunan JY Casting

Normally, there are 13 steps to change new jaw crusher plates: Prepare to work tools:600 live-mouth wrench, wire rope, hand hammer, mast, sledgehammer, electric welding, crane; Prepare

Learn More

How to get the most wear life out of your rotatable one-piece

One-piece and two-piece jaw plates for ® C Series™ jaw crushers are rotatable. But how do you know when to rotate the jaw crusher plate

Learn More

Materials of Jaw-crusher plates and application of Bi-layers

The present paper reviewed the various metal materials for the Jaw-crusher plate used currently in the related machines abroad and domestic,

Learn More

Jaw Crusher Plates - Wear Parts For Industry | Qiming Casting

Our foundry had succeeded to offer jaw plates for crusher, crusher and other famous brands.On the other hand, Qiming Casting also offer a variety of manganese contents, from 14% up to 22% for the more demanding applications. In some means, we also improve material choice and casting technology. Wedges Wedges

Learn More

jaw crushers for all your needs - Lutze Process

Low jaw plate wear. • Large feed acceptance capability. These four factors are closely linked and the jaw crusher provides a good balance. The de-.

Learn More

Jaw Crushers - MEKA Crushing & Screening Plants

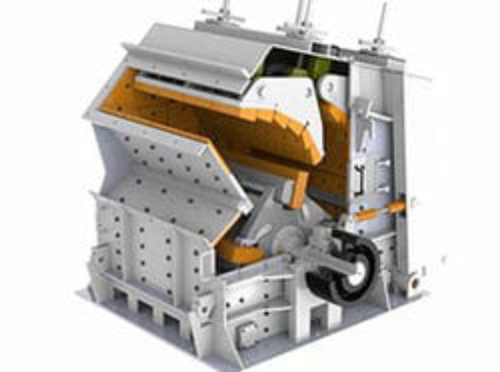

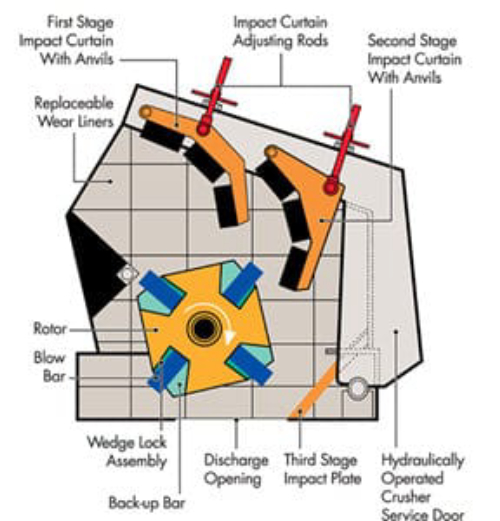

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

Learn More

Source The Ideal Wholesale jaw crusher plate

Create fine powders for industrial projects with crusher machines. Browse the jaw crusher plate range on for all types at wholesale prices.

Learn More

Jaw Crusher Spare parts High Manganese Steel Plate For Jaw Crusher

Lieb HeavyThe jaw crusher is widely used in medium-sized crushing of various ores and bulk materials in mining, smelting, building materials, highway, railway, water conservancy and chemical industries. When the jaw crusher is working, the jaw plate is in direct contact with the material and bears huge crushing force and frictional force of the material.

Learn More

WEAR IN STONE CRUSHER PLATE - IJARIIE

This paper describes the weight reduction of jaw plate and materials for jaw crushers in mining industry.. The interaction between the jaw plates and

Learn More

JAW PLATES - Precision Casting

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing

Learn More

Jaw Concepts | Beaverton OR | Read Reviews + Get a Free Bid - BuildZoom

Jaw Concepts Llc holds a $1,000,000 insurance policy with Ohio Security Insurance Company. Financial recourse when hiring Jaw Concepts Llc Licensed contractors in Oregon are required to carry a surety bond (ranging from $10k up to $75k based on their trade), which provides you with financial recourse in case they perform defective work or

Learn More

Jaw Crusher Wear Parts - Unicast Inc

Increase machine up-time with Unicast Jaw Crusher replacement wear parts including jaw plates, cheek plates, wedges, and toggles.

Learn More

JAW CRUSHER SERIES

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range. Product picture

Learn More

Mn22 Jaw Crusher Wear Plate Jaw Plate Suit C125 Spare Parts

China Mn22 Jaw Crusher Wear Plate Jaw Plate Suit C125 Spare Parts, Find details about China Jaw Crusher Wear Plate, Jaw Crusher Jaw Plate from Mn22 Jaw Crusher Wear Plate Jaw Plate Suit C125 Spare Parts - Jiangsu Hyton Mechanical Equipment Co., Ltd.

Learn More

Toggle Plate | Genuine Alternative Jaw Crusher Parts | GTEK

Toggle Plate is a simple & low-cost but very important part of jaw crusher. It is usually made of cast iron, and it is used to hold the lower part of the jaw in position, it also serves as a safety mechanism for the entire jaw. If something that the jaw crusher cannot crush gets into the crushing chamber accidentally and it cannot pass through

Learn More