primary crusher machine

Primary Crushing - Mineral Processing & Metallurgy

26/02/ · The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in

Learn More

Primary Machinery

888-680-3433, Welcome to Primary Machinery! We sell tub grinders, horizontal grinders, wood chippers, slow speed high torque shredders, rock crushers and more! We buy sell or trade quality, pre-owned, heavy equipment. From Domestic to International sales we can help! Primary Machinery understands the requirements your job demands.

Learn More

Buy Primary Crusher Equipment Stone Jaw

Jaw crusher is a kind of stone crushing machine which is widely used as primary or secondary crusher. Baichy manufactures coarse jaw crusher and fine jaw

Learn More

Jaw Crusher - JXSC Machine

Jaw crushers are mainly used at the primary stage to reduce hard and brittle materials size for the next crushing stages, widely applied in the mining,

Learn More

Primary Crusher For Gold-HN Mining Machinery Manufacturer

Feb 26, The term "primary crusher," by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher for this service

Learn More

Primary Crushing - 911 Metallurgist

The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of

Learn More

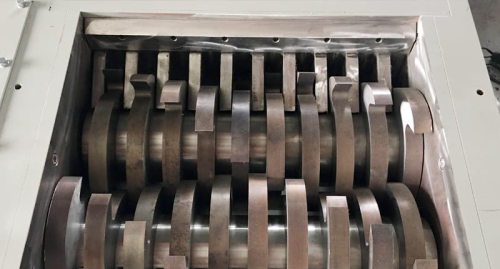

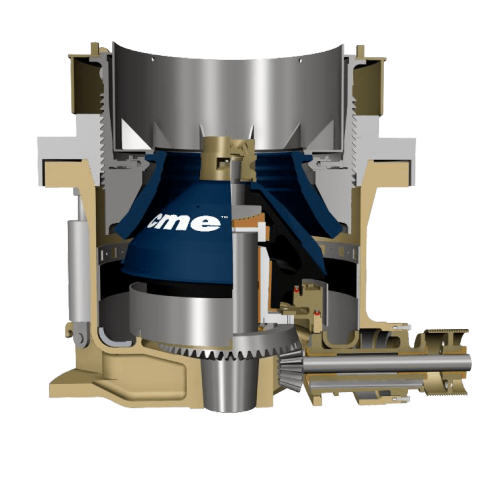

primary gyratory crusher parts | shredder part hammer mill

Gyratory Crusher. Primary gyratory crusher is ideal for tackling large rocks mainly in ore mines and in the natural rock industry Allis Chalmers / Svedala. Allis Chalmers 42-65 Superior Primary Gyratory Bottom Shell Bushing PN 07-250-010-001. .00. decrease. increase. Add to Cart. Add to Wishlist Add to Compare. Quick shop.

Learn More

Stone Crusher Machine 42X08 Manufacturer from Indore

Minimum Order Quantity: 1 Piece; Usage/Application: Industrial; Type Of Crushing Machines: Jaw Crusher; Capacity: 40 TPH; Brand: VINDHYA; Model Name/Number: 101

Learn More

What is a Jaw Crusher? - MEKA Crushing Equipment

In general, crushing is carried out in three stages, depending on the desired size of the material. Primary Crushing. This is the first stage of the crushing process. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm. Secondary Crushing. This is the second stage of crushing.

Learn More

How do we analyze a jaw crusher machine? - Quora

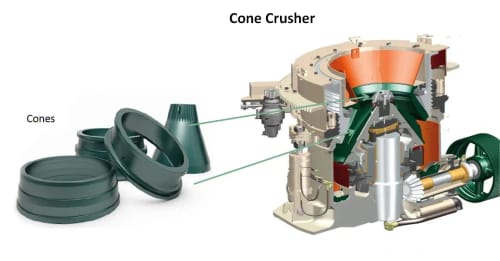

Comparing with cone crusher and impact crusher, jaw crusher is ideal crushing equipment in stone crushing plant. There are so many series of jaw crusher

Learn More

China Primary Crusher Machine Manufacturer and Supplier, Factory

Primary Crusher Machine - Manufacturers, Suppliers, Factory from China We consistently carry out our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Primary Crusher Machine, Small Vibrating Screen For Sale , Gyratory Cone Crusher , Bico Jaw Crusher

Learn More

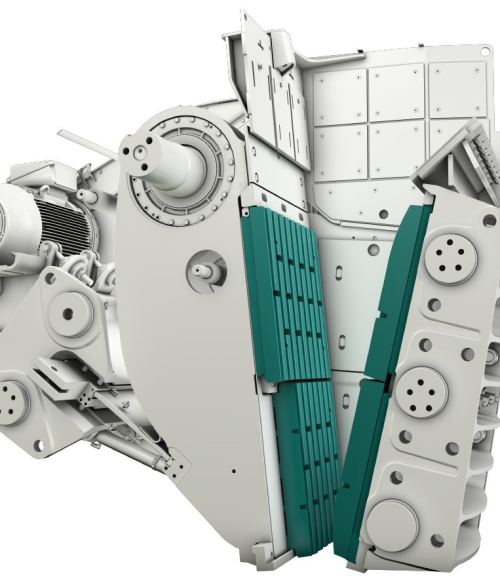

Steele Primary Crushers - Machinery - J.C Steele & Sons

Steele primary crushers deliver cost-effective, reliable sizing for bulk raw overloads on secondary crushing machines and lowering maintenance costs.

Learn More

Primary Jaw Crusher Machine - Alibaba

Create fine powders for industrial projects with crusher machines. Browse the primary jaw crusher machine range on for all types at wholesale prices.

Learn More

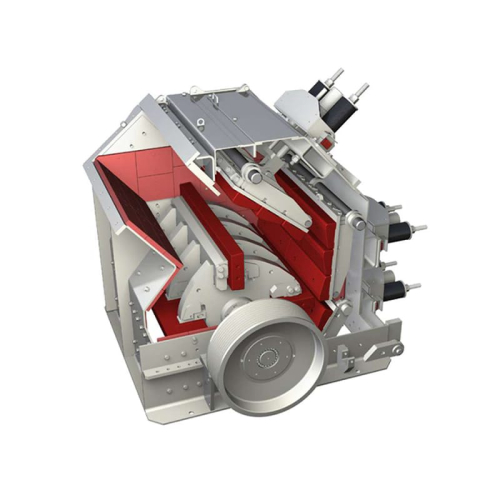

Choosing the right crusher - Buying Guides DirectIndustry

It's a primary crusher. The jaw crusher is a machine for crushing rocks and other hard and abrasive materials, such as granite, ores or recycled concrete,

Learn More

Primary Crushers Machine For Cement

Crushing Plant Design and Layout Considerations. Equipment suppliers are offering ever-larger primary crushers, with 1,800 mm 72 in gyratories expected soon, as well as secondary and tertiary machines of up to 3,000 mm 120 in. Rising energy costs are causing owners to increase the integration of mine and mill concrete wall, which has minimal structural backfill.

Learn More

Primary crusher, Primary crushing and screening plant

Impact crushers can be used as primary crushers, secondary crushers or tertiary crushers depending on the size and technology. They are equipped with beaters, also called hammers,

Learn More

Crusher, Crushing plant - All industrial manufacturers

A crusher uses mechanical energy to break stone blocks into smaller pieces of a desired size. Maximum input size is limited by the machine's design. Several crushing stages may be necessary to obtain the desired final product. Primary and secondary crushers handle large pieces, while tertiary and quaternary models produce finer particles

Learn More

Primary Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Primary Crusher, Primary Crushing Machine, Primary Crusher Primary crusher or primary crushing machine takes an important place in stone crushing plants or grinding mill plants for

Learn More

Different Types Of Crushers Machine Of Primary,secondary And Tertiary

types of primary crushers - Coal processing system Machine The following list describes many of the different types of crushers that crushers,types of crusher,primary seen more often in a secondary or tertiary rock rock types: jaw, impact, mobile, cone, portable rock crusher

Learn More

Primary Crusher Components | Crusher Mills, Cone Crusher, Jaw Crushers

Primary Crusher Components, How jaw crusher work,jaw ore crusher working principle, , Jaw Crushers are ideally suitable for primary and secondary crushing, with low power consumption and easy maintenance. , Jaw Crusher Components 1 Frame, Crusher - Wikipedia, the free encyclopedia,

Learn More

TLC for Primary Crushers | E & MJ

A primary crusher that is underperforming will also impact upon every other piece of downstream equipment, quickly causing a bottleneck and, potentially, a source of lost revenue. E&MJ asked three global OEMs and service providers how best to care for these machines. Preventative Maintenance. Assuming the correct gyratory model has been

Learn More