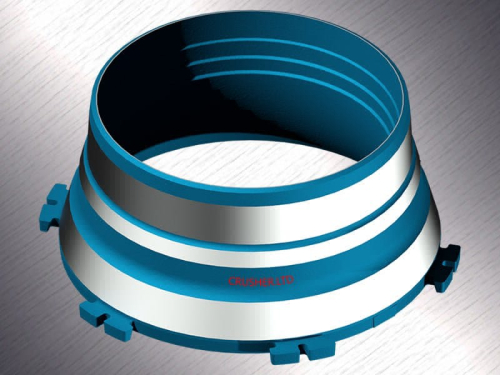

cone cursher liner

Cone Crusher Liners Selection - Wear Parts For Industry - Qiming Casting

2.Crusher Liner's Material Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

Learn More

cone cursher liner | grasslands countershaft bushing mill

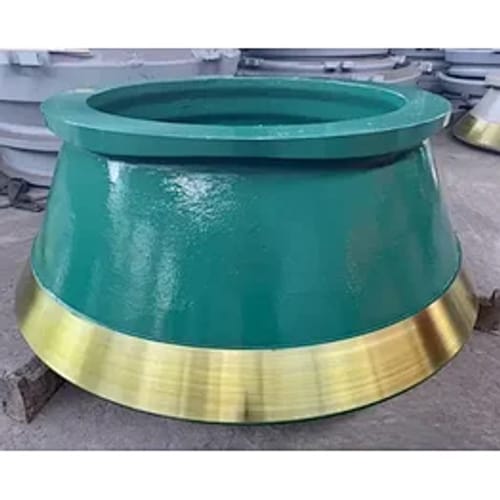

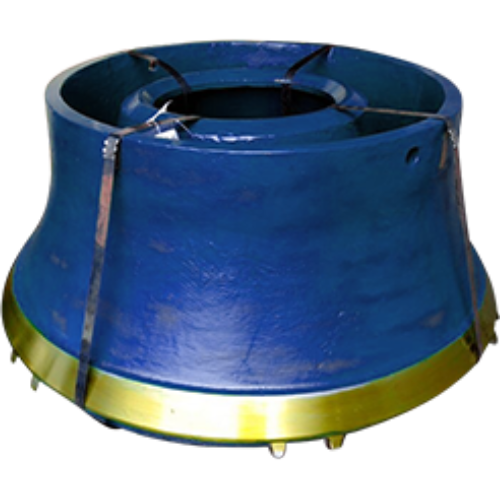

Cone Crusher Liners - EB Castworld % Cone Crusher Liners. Cone Crusher Liner has the characteristics of beautiful appearance, high internal quality, resistance to emptiness, wear, extrusion, and long service life. It fully meets the requirements of the concentrator for the use of Cone Crusher Liner: Cone

Learn More

Cone Crusher Liners: How to Select and When to Change

6/23 · 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

Cone Crusher Liner - China Factory, Suppliers, Manufacturers

Cone Crusher Liner In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of Cone Crusher Liner, Impact Crusher Spare Parts , Ball Mill Rubber Lining , Cone Crusher Concave , Stone Grinding Mill .

Learn More

Cone Crusher Liners | Manufacturing and service of Gyratory

In order to help your site maximise its operational performance, we design Cone Crusher Liners and wear parts that are tailored specifically with your needs and

Learn More

Fisher Industries hiring Crusher Operator in Livingston, Montana

Fisher Industries is a family of businesses that encompass all aspects of the aggregate production and heavy civil construction industries. Our unique, vertically-integrated business model allows

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

Cone crusher liners material selection There are 4 types of cone crusher liners materials: Manganese steel. Manganese steel, also called Hadfield steel or Mangalloy, is a steel alloy containing 12-14% manganese. Renowned for its high impact strength and

Learn More

Crusher Liners | World-Leading Crusher Liners | CMS Cepcor

The crusher liners by CMS Cepcor® often exceed the performance of the original manufacturer parts. Contact us today to find out about our range of liners. +1-877-CEPCOR1 (+1-877-2372671)

Learn More

Cone Crusher | Hazemag North America

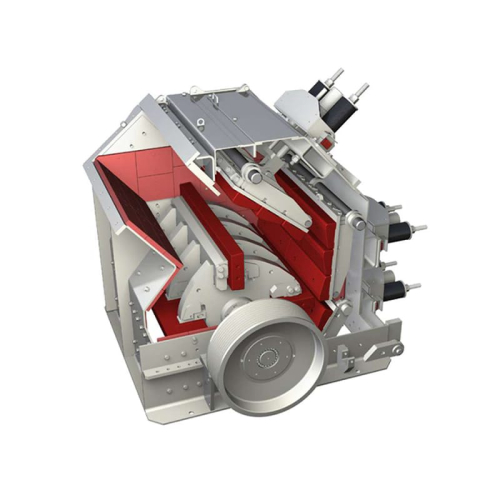

Cone Crusher KEY FEATURES High Crushing Capacity range of 100 - 1500 short ton/hour Patented Insert Mantle and Concave Liners which leads to energy savings of up to 30% Latest Safety Features compliant with CE regulations GET MORE INFO Contact Us Request a Brochure Product Description Technical Data Cone Crusher Product Description Technical Data

Learn More

Cone Crusher Liners - Hunan JY Casting

Cone Crushers have been the standard technology in cone crushing for over 70 years and Hunan JY Casting has been making cone crusher liners for this large population of crushers for nearly as long, providing better customer support than typical parts suppliers.

Learn More

cone crusher liner selection - Wear Parts For Industry - Qiming Casting

The manganese trademark : Mn13CrMo, Mn18Cr2Mo, Mn13Cr2Mo. Cone crusher liner selection chemical elements from Qiming Casting Test Report. From the test report, Mn13 is the high manganese steel and Mn18 is Ultra-high manganese steel, The content of elements "Si" can effect the Impact toughness , need less than 0.5%,the lower content of

Learn More

Cone Crusher Liners | Manufacturing and service of Gyratory Crushers

Cone Crusher Liners — find the correct solution for your application. Using our knowledge as an Original Equipment Manufacturer (OEM), we ensure that the supplied product is correct for your equipment and application. We offer Cone Crusher Liners tailored to your needs and manufactured to help you find increased productivity.

Learn More

Cone Crusher Liners | Crushing Wear Parts

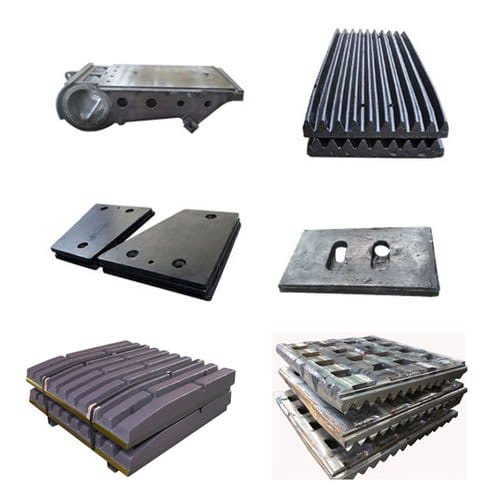

Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone crushers, impact crushers and roll crushers – optimized for any size

Learn More

Cone Crusher Solutions - Bradken

Overview · Customised liner profiles to suit all operating conditions · Manganese grades to cover all applications · Direct Replacement Part(DRP) crusher liners

Learn More

Cone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn More

bowl liner for cone crusher | crusher eccentric wearing plate australia

Cone crusher parts : Bowl Liner and Mantle Crusher wear. Cone Crushers for Mining: Cone Crusher Bowl Liners and Mantles for Extreme Conditions Because of the extreme crushing conditions experienced by the crushers used in mining operations, special attention must be paid to the materials used in producing these castings. h6800 series cone

Learn More

Cone Crushers | McLanahan

Features & Benefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Learn More

What is a cone crusher mantle? - Sandrock Mining

6/11 · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn More

Geometric analysis of cone crusher liner shape

Cone crushers are in common use wherever crushing is required. Cone crushing for aggregate production far exceeds all other applications

Learn More

Prediction of Cone Crusher Performance Considering Liner

Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences

Learn More