cement cooler

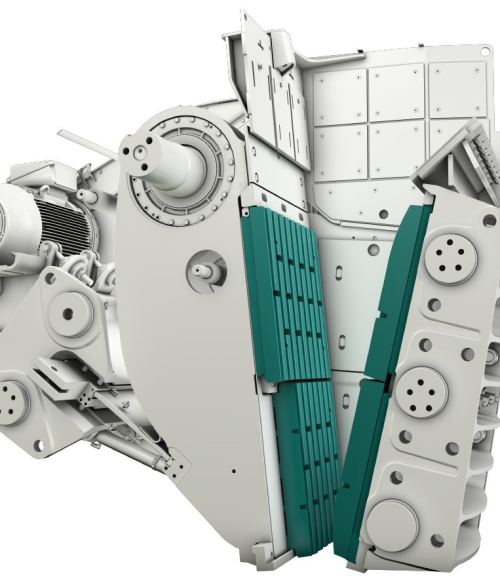

Grate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

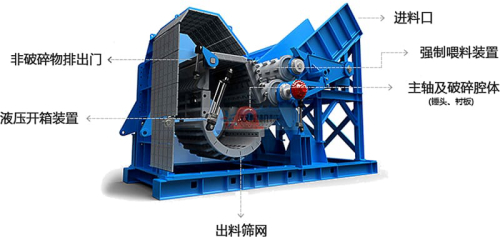

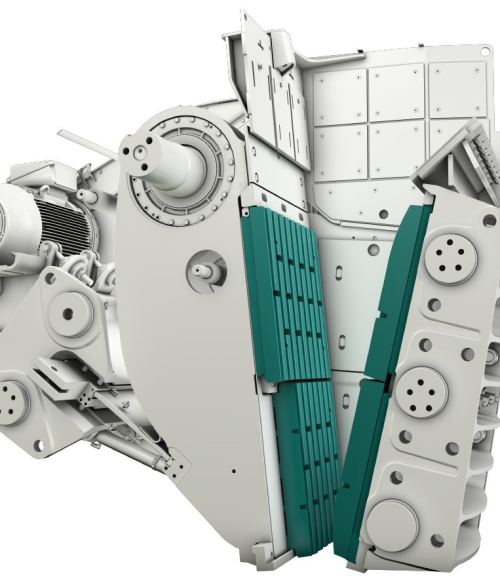

The grate cooler adopts a modular construction design, is flexibly adaptable to different scales of the cement kiln. There is no need of conveying equipment for material leakage under the grate

Learn More

Concrete Cooler | Etsy

Check out our concrete cooler selection for the very best in unique or custom, handmade pieces from our coolers shops.

Learn More

1 in Cement/Concrete Cooling in Hillsboro OR

1 Source for Emergency & Temporary Cement/Concrete Cooling in Hillsboro OR = Paratus Rentals 855-313-7368 If you use cold water to help hydration in your aggregate mixing process, we have the help you are looking for. Paratus Rentals is your #1 source for Cement/Concrete Cooling in Hillsboro OR! If you are operating a Cement/Concrete plant in

Learn More

Cement Cooling System - Efficient, Industrial Cement Cooler

The Solex heat exchanger is capable of handling any relatively free-flowing powder or crystalline bulk solids, making it the perfect candidate to cool cement,

Learn More

Find a recycler | Metro

Loads of mixed dirt, rock, asphalt and concrete. May include other fill materials, but no organic materials. Some recyclers may accept red brick in the mix. Salvaged and used building material More information. Used building materials in good reusable condition. Contact the recycler for information about specific materials. Sand; Sawdust; Terra

Learn More

Clinker Cooler - Grate Cooler Latest Price, Manufacturers

Coolers are used with rotary kilns to rapidly cool hot clinker or other materials exiting the kiln. - The latest generation clinker cooler of Sinoma-tec has

Learn More

Rotary Cooler for Small Cement Plants | Rotary Drum

The latest type of rotary cooler can cool the fresh cement clinker to 150 ~ 250 ℃ and provide secondary air at 700 ~ 800 ℃ for the rotary kiln. Its overall thermal efficiency can reach 55% ~

Learn More

performance evaluation of a grate cooler in a cement ... - IJSEAS

this study, the performance of a grate cooler in Ibese cement manufacturing industry in. Nigeria has been examined using the mass and heat

Learn More

Concrete Freezer & Cooler Crack Repair Products | KwikBond

KWIK-BOND is designed for industrial concrete floor repair on frozen surfaces such as freezers, coolers, and holding boxes. You can set up and cure without the need to raise surface temperatures, use propane torches, or heating lamps to accelerate the cure. KWIK-BOND can be used anywhere a quick set is desired, in any temperature range.

Learn More

Cement Euipment Overview | Cement Making Machines | Cement Plant

The cement cooler is also used for clinker production. Using blower blowing cold air, quench the cement clinker that laid on the grate plate, decrease the temperature of clinker from 1200℃ to 100℃ and below, the cooling exhaust gas enters into the kiln as secondary air. dryer In fact, every cement plant requires different cement equipment.

Learn More

PDF) The effects of grate clinker cooler on specific energy

This study focuses on grate clinker coolers (GCC) which are used to recover heat from hot clinker produced in rotary kiln (RK) in cement

Learn More

White cement cooler - thyssenkrupp Industrial Solutions

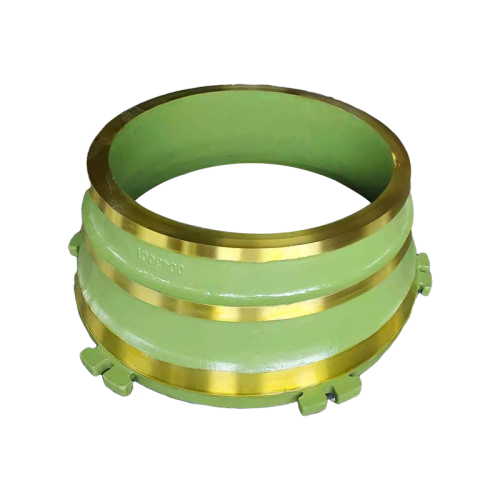

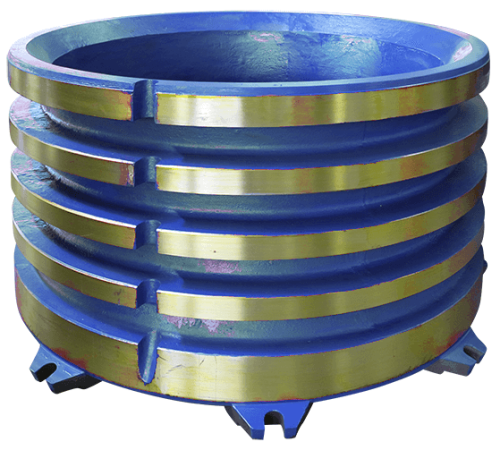

Especially for the white cement production process, thyssenkrupp Industrial Solutions developed the twin cooler, consisting of rotary cooler, roll crusher

Learn More

Rotary Cooler - Cement Cooler | AGICO Cooler In Cement Plant

The main purpose of cement rotary cooler: Reduce the temperature of the clinker as low as possible for subsequent grinding, transportation, and storage. Recycle the heat energy from the clinker as much as possible to heat the secondary and tertiary air, making them combustion air and minimizing the fuel consumption of the cement rotary kiln system.

Learn More

Cement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

The thermal efficiency of a cement cooler refers to the percentage of the total heat recovered from the high-temperature clinker and the physical heat of the clinker. The higher the thermal

Learn More

Grate Cooler - INFINITY FOR CEMENT EQUIPMENT

2.2 Reciprocating Grate cooler · It have been used for years as an effective means for clinker cooling · The basic concept of the grate cooler is quite simple

Learn More

Pyrofloor²® - KHD Humboldt Wedag

The cooler is the last step in the clinker production process. In fact, at a Turkish cement plant that was among the first Pyrofloor® cooler

Learn More

Evaluating the thermodynamic efficiency of the cement grate

ASPEN Plus and neural networks predictive model were used to model, simulate and predict the grate clinker cooler in this paper. First, the process flow model

Learn More

CN103743264A - Cement rapid cooler - Google Patents

1. a cement flash cooler, is characterized in that: comprise air blast (1), cooler bin (2), dust arrester installation (3); described cooler bin (2) top is provided with hot cement entrance (4),

Learn More

Office Water Coolers Hillsboro

Hillsboro Water Cooler Systems. Choose from the largeest selection of office water dispensers in Hillsboro We provide low priced water coolers and bottleless water machines all over the state of Hillsboro from top brands of bottleless point of use water machines like Brio, Oasis water coolers, Atlantis bottleless machines, Kenmore, G3 and Clover water cooler models.

Learn More

Clinker Cooler - 911 Metallurgist

The Air-Quenching shaking grate Clinker Cooler was developed more than 20 years ago as an improved heat recuperating cooler for use with

Learn More

Cement Cooling System - Efficient, Industrial Cement Cooler | Solex - Solex

The cooling of cement is an important step prior to storage in mitigating gypsum dehydration and subsequent moisture liberation which can lead to lump formation. Recommendations vary but it is generally accepted that with mill outlet temperatures of around 110ºC - 120ºC, cooling to below 80ºC is necessary to avoid this reaction.

Learn More