what is a cone crusher

Hydraulic Cone Crusher, Stone and Construction Waste Crushing

Hydraulic Cone Crusher. The cone crusher integrates mechanical, hydraulic, electrical, automatic and intelligent control, and adopts the principle of layer compression crushing, which is able to crush hard materials such as masonry and stone in construction and decoration waste to a small size, and the finished product is of high quality, with

Learn More

Why do cone crushers need full cavity feeding?-Jiaozuo zhongxin heavy

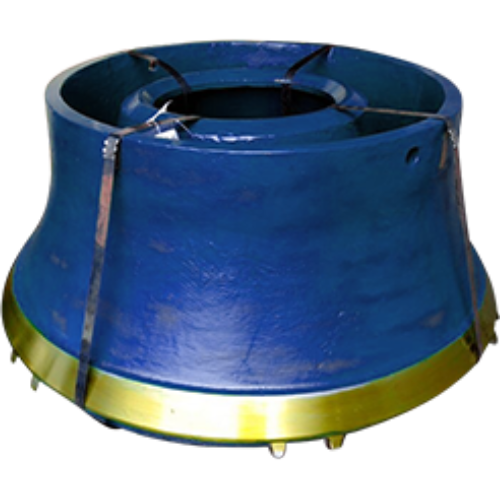

The crushing cavity of the cone crusher is the space formed between two moving parts, that is, the space between the fixed cone lining plate and the moving cone lining plate. That is to say, the upper part of the crushing cavity is the feeding space, and the lower part is the discharging space. Therefore, when the cone crusher is full of materials, the crushing cavity can only be filled with

Learn More

What Is A Hydraulic Cone Crusher? - Machinery

The single-cylinder hydraulic cone crusher has a new crusher structure, optimized laminated crushing cavity type, and a fully intelligent automation control system. In general, it can be widely used in medium crushing, fine crushing, and ultra-fine crushing operations. The working site of the cone crusher in India.

Learn More

High-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

The ZI Cone Crusher, launched in as a strategic model for overseas markets, was developed to meet the market demand for high efficiency

Learn More

Cone crushers - for demanding crushing needs - Outotec

Cone crushers are popular rock crushing machines in aggregates production, mining operations, and recycling applications. They are normally used in secondary, tertiary, and quaternary crushing stages.

Learn More

What is a Cone Crusher? - Definition from Trenchlesspedia

12/9 · The cone crusher, introduced by the brothers of Milwaukee in the 1920s, is a durable and simple solution that has made its mark. The technology continues to develop, and

Learn More

What Is a Cone Crusher and What Can It Do for You?

4/24 · Apr 24, . A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like

Learn More

Cone Crusher | Working Principle | Animation | Engineering Intro

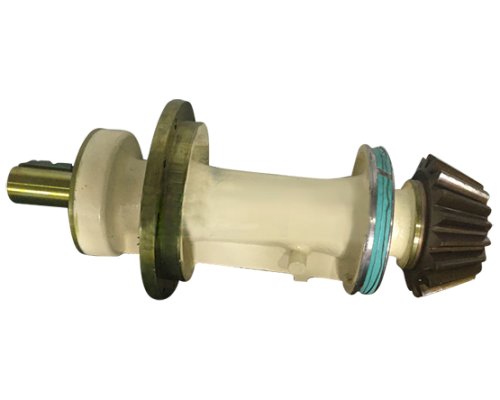

8/15 · Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles.

Learn More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points

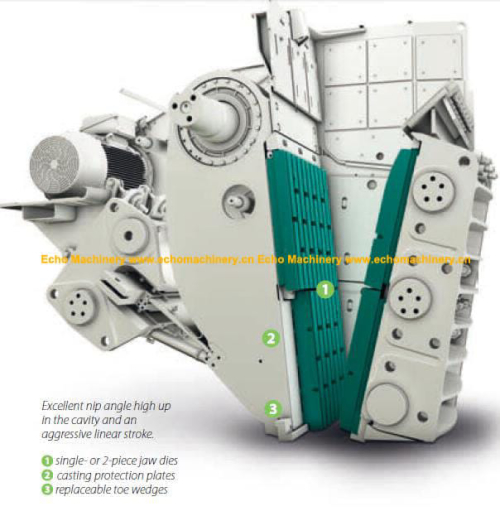

Jaw crushers: The first choice for primary crushing The jaw crusher is popular because it crushes big rocks into smaller sizes easily. Thus,

Learn More

Cone Crusher - Mineral Processing & Metallurgy

4/19 · The cone crusher is usually set to give a 3/8-in. or ½-in. product when discharging to ball mills. Table 9 gives particulars of the different sizes of crushers. The capacity figures are based on material weighing 100 lb. per cubic foot and must be

Learn More

Should I Choose an Impact Rock Crusher or Cone Crusher? - Sepro Aggregates

Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size. If set at 2", typically 80% of the final product will meet the 2" target which is not something that can be replicated by jaw crushers or impact crushers.

Learn More

What is the crushing capacity of the cone crusher?

The crushing capacity of a cone crusher refers to the amount of material crushed per unit time, usually in tons/hour. 1. The hardness of the material. The harder the material, the more difficult it is to break, and the more severe the wear of the equipment. The crushing speed is very slow, and of course the crushing ability is also very small.

Learn More

Cone Crusher - an overview | ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are

Learn More

Patriot® Cone Crusher - Superior Industries

Typically applied in secondary and tertiary stages, the cone crusher produces reduction ratios of 6:1 to 4:1. Bushing cones, like Superior's Patriot Cone

Learn More

Common Faults and Solutions of Cone Crusher

Replace the oil pan and thrust plate. 2. Oil temperature and oil pressure rise. The oil pressure in the thin oil lubrication system of the cone crusher increases and the oil return temperature also rises accordingly. The reason. The oil pipe or the oil groove in the crusher parts is blocked, and the safety valve fails.

Learn More

The Differences Between Cone Crusher and Impact Crusher

Impact crusher uses the principle of impact crushing During operation, driven by the motor, the rotor rotates at a high speed. When the material enters the blow hammer effect area, it collides with the blow hammer on the rotor and breaks, and then is thrown to the counterattack equipment to be broken again, and then bounces back from the counterattack liner.

Learn More

What is a Cone Crusher| Advantages, Types, Parts and

Cone Crusher Advantages. Laminated crushing, high crushing efficiency, good shape of the discharged material. Medium and fine crushing cavity type, easy to switch, multi-purpose in

Learn More

What Is Cone Crushers And How Does It Work In India

Want to know how does impact crusher work rock crusher the impact crusher is a macple the materials in the crushing chamber suffer a high speed crush from the highspeed rotating. Cone Crushers. With features of reliable structure, high working efficiency and easy adjustment. Sand

Learn More

Type of crushers and their difference - JXSC Mining

A cone crusher is suitable for crushing a variety of mid-hard and above mid-hard materials. The feed is dropped to the crusher from the top and it is crushed between the crushing chamber and the slowly rotating cone. Cone crushers are mostly used for the large scale crushing in the mining industry.

Learn More

What Are Cone Crushers? - Engineering World

Cone crusher is a type of machine widely used in urban construction, which basically reduces the size of the material with the help of compression, squeezing or breaking down between

Learn More

Cone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed

Learn More