gyratory crusher mantle

mantle of cone crusher position | Mining & Quarry Plant

26/04/ · Cone Crusher Mantle 183 open Crusher Jobs available on Indeed.com, the world’s #1 Job site. Crusher Wikipedia. A cone crusher is similar in operation to a gyratory crusher, Mantle is installed in the lower position and concave in

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 2

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn More

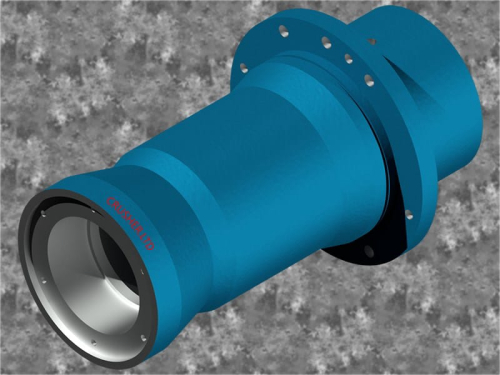

CSP Gyratory Crusher Wear Parts

We offer high-quality replacement gyratory crusher wear parts, including: Liners Mantles Spider caps Spider arms Spider bushing Bottom shell bushing Pinion and gear Step bearings CSP manufactures concaves and mantles for Allis-Chalmers and Fuller/Traylor gyratory crushers. One-, Two- and Three-Piece Configurations are available.

Learn More

Gyratory Crusher Mantles - Columbia Steel Casting Co., Inc

We produce mantles that are self seating / self positioning, or OEM-type mantles with manual wedge positioning. Depending on application, we’ll recommend our R57, L68, L78, or L88

Learn More

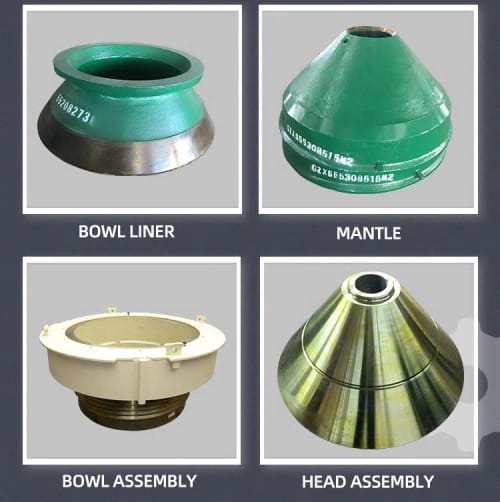

Gyratory Crusher Parts - Mayang Crusher Parts

Mining Industry Concave, Mantle, Bowl liner, Spider shield, Spider Cap. For over 35 decades, Mayang has applied the same engineering problem-solving to gyratory crushers which has proven so effective on cone crushers. We went into the field and studied the many areas for potential improvement: poor nip of feed material, excessive wear in the

Learn More

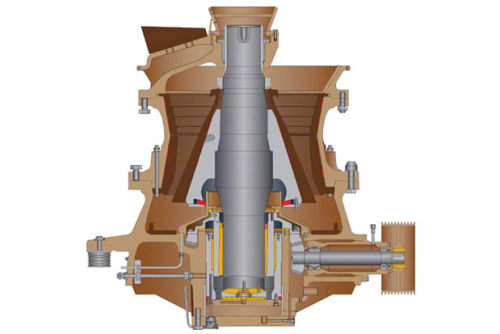

Gyratory and Cone Crusher - ScienceDirect

01/01/ · Figure 5.1 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines. Variations in the design of the breaking head and the mantle have been adopted by different manufacturers. Such variations are adopted from studies on stress distributions of component parts endured during

Learn More

CSP Gyratory Crusher Wear Parts - Cast Steel Products

MANTLE, 07-344-404-001, 610401. 14999-D, 610403. CONE AC 1384, MANTLE, 07-349-708-001, 610601. CONE AC 3-1/2 51, MANTLE, 11122-H, 610301.

Learn More

Mantle Archives - Mayang Crusher Parts

Mantle - Mayang Crusher Parts. High quality and low price Mantle-Cone crusher wear parts

Learn More

Gyratory Crusher (GY model)| Crushing/Grinding

Gyratory Crusher (GY model)' Design is a combination of the most modern engineering techniques. ・Our newest 60-109 GY provided to (Mantle Dia,MAX)

Learn More

Gyratory Crushers - Sandrock Mining

Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining

Jaw Gyratory Crusher Pro – the next generation of thyssenkrupp´s unique bestseller for crushing is now available. The main characteristic of jaw gyratory crushers is their enlarged feed

Learn More

Mantle Segments For Krupp Superior FZE Primary Gyratory Crushers

Created with Sketch. 邮箱. [email protected] . whatspp:+86 15958452539. whatspp:+86 15958452539

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

17/02/ · Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″

Learn More

Torque Analysis of a Gyratory Crusher with the Discrete

The functional principle of the machine is to compress the ore among the mantle and the concave. To achieve particle compression, the main shaft rotates

Learn More

Gyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore Gyratory crushers are designated in size either by the gape and mantle

Learn More

Superior™ MKIII 60-89 primary gyratory crusher - Outotec

Superior™ MKIII 60-89 primary gyratory crusher provides increased throughput coming from increased speed and installed power that brings overall benefits to your primary crushing circuit. High throughput Reduced downtime Fast wear parts exchange Increased safety

Learn More

EP0093069A2 - Anti-spin device for cone crusher - Google

B02C2/047 Crushing or disintegrating by gyratory or cone crushers eccentrically 4) The liner and mantle for the crushing bowl and the crusher head are

Learn More

Method for securing a gyratory crusher mantle - Google Patents

The mantle can loosen from the main shaft. If the gyratory crusher is not shut off, the free spinning mantle can cause extensive damage to the crusher. The

Learn More

Gyratory crusher mantle-bowl structure - Google Patents

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing

Learn More

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

Jaw gyratory crushers - design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn More

Improving Gyratory Crusher Perform

each mantle. Since H-E Parts improved the material selection and implemented a mantle and concave redesign, the following has been achieved:.

Learn More