plastic extrusion emission factors

Compositions of Volatile Organic Compounds Emitted from Melted

emissions from plastics during melting processes.3-8Most of these studies have indicated that the emitted VOCs originated from polymer degradation. However, there might be additional mechanisms responsible for the VOC emissions. For instance, plastic additives such as antioxi- dants and plasticizer are expected to affect the composi-

Learn More

An Environmental Analysis of Injection Molding - DSpace@MIT

Figure 22 - Plastic Demand in Southeast Asia. Table 29 - Main sources of emissions in an injection molding facility 71.

Learn More

Plastic Product Manufacturing - City of Toronto

10, Input summary: Enter the amount of plastic product manufactured 19, Polyethylene Extrusion 14, Emission Factors (lb/ton of plastic produced).

Learn More

PDF 6.9 Synthetic FibersPDF

processes, these emissions are discussed in Sections 6.6, "Plastics", and 6.10, "Synthetic Rubber". Examination of VOC pollutant emissions from the synthetic fibers industry has recently concentrated on those fiber production processes that use an organic solvent to dissolve the polymer for extrusion or that use an organic solvent in some other

Learn More

Plastic and Resin Industries Emission Control - Technologies

Plastic and Resin Industries Emission Control has successfully addressed emissions from a broad variety of plants in the plastic and resin industries including at rigid packaging, flexible packaging, resin production, pultruded products, foam products, thermoplastic roofing, specialty film and sheet, and other plants.

Learn More

What is the air emission factor for a PVC blown film extrusion process?

21st Jun, 2017. Jerry Decker. Retired Engineer. PVC will melt in blow molding, but should be essentially free of volatile components before that step. You wont find data on PVC vapor, but you will

Learn More

EPA Sector Notebook Project - Profile of the Plastic Resin and

operations include primarily VOC emissions (Kroschwitz, 1986). III.A.4. Polymer Extrusion. Most polymers undergo further processing steps to form plastic

Learn More

EIIP Vol. II, CH 11: Preferred and Alternative Methods for

of the Emission Inventory Improvement Program and for Roy Huntley of the Emission Factor and Inventory Group, U.S. Environmental Protection Agency. Members of the Point Sources Committee contributing to the preparation of this document are: Denise Alston-Guiden, Galson Consulting Dennis Beauregard, Emission Factor and Inventory Group, U.S. Environmental

Learn More

3. Greenhouse Gas Emissions from the Plastics Processing Industry - NRCan

The factors used to estimate the emissions of CO2, CH4 and N2O resulting from the combustion of natural gas (which represents approximately 85 percent of the plastics product sector direct emissions) are shown in Table 3-2. The CH4 and N2O emissions are minor compared to the CO2 emissions.

Learn More

Factors which affect the basic process of plastics

Plastic Extrusion LED Lamp Shade/Cover/Tube. Plastic Extrusion PC Profiles/Pipes. Plastic Extrusion PP Profiles/Pipes. Factors which affect the basic process of plastics. Jul. 01, . Factors affect the basic process of plastics shared by Custom PE Plastic Extrusion Profile supplier.

Learn More

AP 42 Section 4.4 Polyester Resin Plastic Products

16/02/2007 · As an alternative to estimating open molding emissions using reference 9 (G. A. LaFlam, Emission Factor Documentation For AP-42 Section 4.12: Polyester Resin Plastics

Learn More

Development of Emission Factors for Polyethylene ... - PubMed

Emission factors for selected volatile organic and particulate emissions were developed over a range of temperatures during extrusion of polyethylene resins

Learn More

Development of Emission Factors for Ethylene-Vinyl Acetate and ... - PubMed

Emission factors for selected volatile organic compounds (VOCs) and particulate emissions were developed over a range of temperatures during extrusion of three mixtures of ethylene-vinyl acetate (EVA) copolymers and two mixtures of ethylene-methyl acrylate (EMA) copolymers. A mixture of low-density polyethylene (LDPE) resins was used as a control.

Learn More

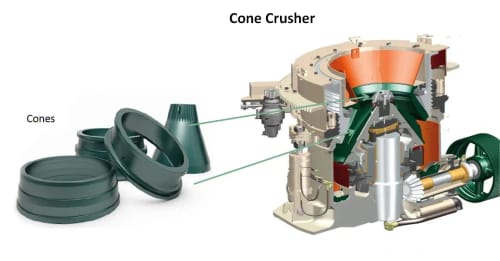

C100 INTERMED FLANGE LS-250 | plastic extrusion emission factors

crusher machine head bush images plastic extrusion emission factors cone crusher mantle liner impact crusher spare inner bushing price cone crusher liner selection. SEDA Hydraulic. Parker 19029200225 EHV 50-250-330 DIA50 SPARE KIT. Parker 11062400225 VEJIGA 50L DIAM.50 VALV.ALEMA.

Learn More

Emission Estimation Technique Manual

9 - Emission Factors for the Continuous Polystyrene Manufacturing monomers for chemical products (ie. plastic raw material), please refer to the

Learn More

Rubber and plastic products - Documentation Base Carbone

Except where stated otherwise, the uncertainty for all emission factors for plastics is 20%, which means that for a plastic with an emission factor of 2,550

Learn More

3. Greenhouse Gas Emissions from the Plastics Processing

There are minor quantities of HFC s emitted from the extruded polystyrene and Table 3-2 Emission Factors from Natural Gas Combustion

Learn More

ORIGINAL - Illinois Pollution Control Board

As I will discuss later, this is why the emission factors developed for extrusion processes are appropriate for the P1M process. Plastic

Learn More

00018D9A.pdf - Florida Department of Environmental Protection

The RAI requested that CPFC assign a different emission factor for vinyl chloride. (VOC) emissions from the PVC pipe extrusion process.

Learn More

XLS City of TorontoXLS

Emission Calculation Fact Sheet, Plastics Production and Products Manufacturing, Michigan Department of Environmental Quality. Particulate Matter emissions = VOC emissions = 3,000,000 kg/yr X 0.1302 lb/ton X 0.4536 kg/lb ÷ 907.185kg/ton 3,000,000 kg/yr X 0.0614 lb/ton X 0.4536 kg/lb ÷ 907.185kg/ton Sample Calculations: Adhesives Production Extruder

Learn More

Documentation for Greenhouse Gas Emission and Energy Factors

emissions per short ton of glass generated for each materials management alternative as shown in Exhibit 1-4. For additional discussion on the detailed methodology used to develop these emission factors, see sections 1.3 and 1.4. Exhibit 1-4: Net Emissions for Glass under Each Materials Management Option (MTCO 2 E/Short Ton) Material Net Source

Learn More