plastic bottle crusher machine project report pdf

Design and Development of a Plastic Bottle Crusher – IJERT

10/14 · STEPS IN FABRICATION. Fabrication of the bottle crusher was divided into 4 stages. It consists of the fabrication of base structure, its components, transmission system and the reciprocating system. The different processes followed in the fabrication of these components is elaborated under the following heads.

Learn More

An Automatic CAN or Plastic Bottle Crusher Machine - IJSRD

An Automatic CAN or Plastic Bottle Crusher Machine - A Review. Vishal N. Kshirsagar Pahang in the year Nov. in his project report entitled.

Learn More

C125 SUPPORT | plastic bottle crusher machine project report pdf

CJ612 4448 Jaw Crusher Screen Jaw Combo Cone Crushers CH660 Hydrocone CH550 Hydrocone CH540 Hydrocone CH440 Hydrocone CH430 Hydrocone CS660 Gyrocone CS550 Gyrocone CS440 Gyrocone Closed Circuit Crushing Plant CH430 Self-contained

Learn More

project report on machine

Stone Crusher Machine Project Report Pdf abpc in . An Automatic CAN or Plastic Bottle Crusher Machine An Automatic CAN or Plastic Bottle Crusher Machine Pahang in the year Nov in his project report entitled . Shadab Husain Mohammad Shadab Sheikh .

Learn More

PDF) Design and Development of Plastic Crusher for a More

PDF | Abstract: One of the prevalent environmental problems Plastic crusher is a machine that reduces used plastic bottles to smaller

Learn More

AN AUTOMATIC APPROACH FOR CAN/ PLASTIC BOTTLE

This project consists of designing and fabrication of an automatic can/bottle crusher machine. In order to reduce the waste, we planned to create a Vishal

Learn More

plastic bottle crusher machine project report

plastic bottle crusher machine project - brela-ubytovanieu - Know More. plastic bottle crusher machine project GEP Ecotech is a solid waste recycling solution provider We manufacture industrial shredder and waste disposal equipmentThe solutions provided by GEP Ecotech are widely used in municipal solid waste recycling, commercial and industrial waste recycling, construction and demolition

Learn More

Design and Fabrication of Plastic Bottle and For

The can and bottle crusher machine is widely used in beverage industries/scrap dealers shop Its wide usability (bottle and can) is backbone of this project.

Learn More

4 project report format for a crusher machine.pdf - Home

View 4 project report format for a crusher machine.pdf from MACHINE LE CS104 at Cochin University of Science and Technology. Home / Project Report Format For A Crusher Machine Project Report Format. Study Resources. Main Menu; by School; by Literature Title; by Subject; by Study Guides; Textbook Solutions Expert Tutors Earn.

Learn More

Design and Fabrication of Water Bottle Crusher

INTRODUCTION Recycling is a series of activities that includes the collection of used, reused, or unused items that would A water bottle crusher can be defined as a device used for otherwise be considered waste, sorting and processing the crushing plastic bottle for easier storage in recycling bins recyclable products into raw materials, and

Learn More

High Efficiency Plastic Bottle Crushing Machine, Plastic Bottle Crusher

This plastic bottle crushing machine consists of drive motor, main rotor, rotary blades, stationary blades, screen, mechanical unit for opening top cover, machine body and water spray pipe, etc. By the plastic bottle crushing machine, the waste plastic bottles will be processed into flakes with indicated sizes for good washing results.

Learn More

PDF) Design and Development of Plastic Crusher for a

8/31 · The efficiency of crushing based on polymers processed are 90% for HDPE, 68% for LDPE, 45% for PVC and 10% for PET bottles. The developed crusher can be used to reduce

Learn More

PDF) Project Proposal for Post-Consumer Plastic Recycling Project

Abstract and Figures. The project is laid out basically under 4 main branches of (a).collecting plastics from rural areas (b), purification of chemical barrels (c) crushing plastics and (d

Learn More

Plastic Recycling Vending Machine - IOSR Journals

here with a solution E-eco Bin. It is a device that accepts plastic pet bottles and rewards the user with a candy. The inserted bottle will be crushed into minute granules. The output of the E-eco Bin can be used for recycling, road making etc. Keywords: , PET,

Learn More

New Design Of A Plastic Bottle Crusher

The basic idea behind this project is to manufacture such a machine crusher that could be placed on recycle cans and crushing operation could be carried out

Learn More

PDF J o u r n a l ofW International ournal a l R I of aste esourcesPDF

To obtain 435 kg of plastic 21750 plastic bottles should be crushed. As 3 bottles are crushed in one cycle, time required to crush the bottles is 21750 minute (21750/3 = 7250 × 3 minute= 21750 minute). Which is equivalent to 362 hours, considering one shift of 8 hours we can complete it at 45 shifts means 45 days.

Learn More

Crusher Machine, plastic crusher machine - MOOGE TECH

MOOGE manufactured plastic crusher machine is mainly used in the plastic recycling line for size reduction. We have plastic pe film crusher, plastic pp woven bags crusher machine, pe pp plastic bottle crusher machine, PVC pipe crusher machine, pet fiber crusher machine, pet strap crusher machine, etc. The crusher can work with water so as to

Learn More

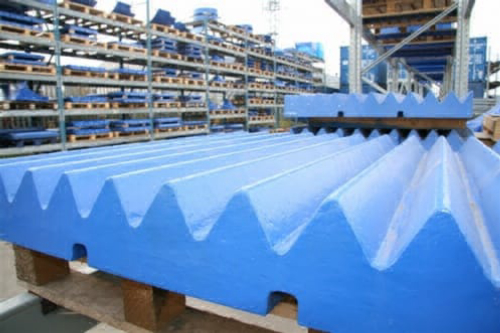

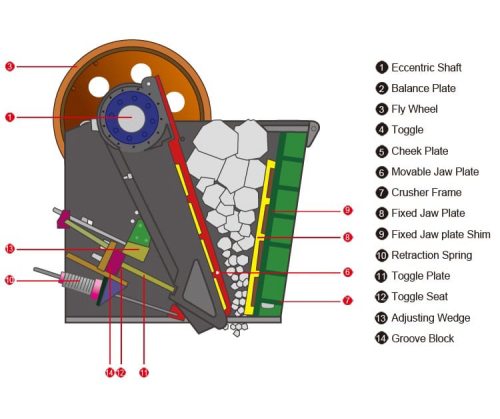

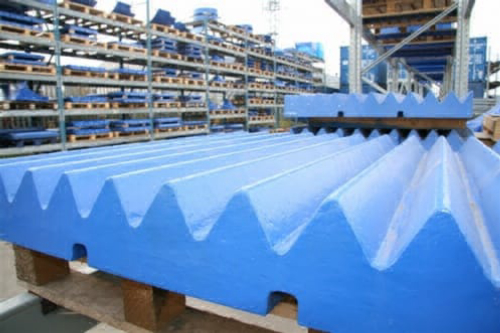

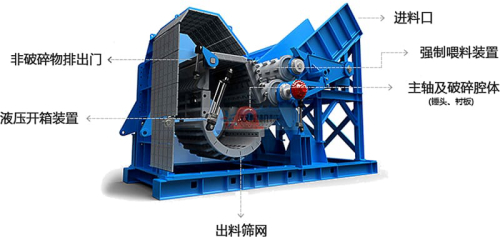

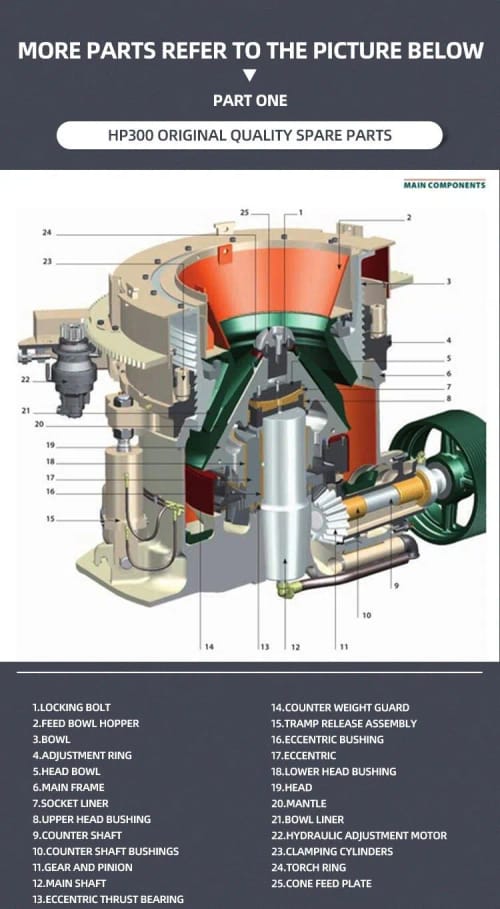

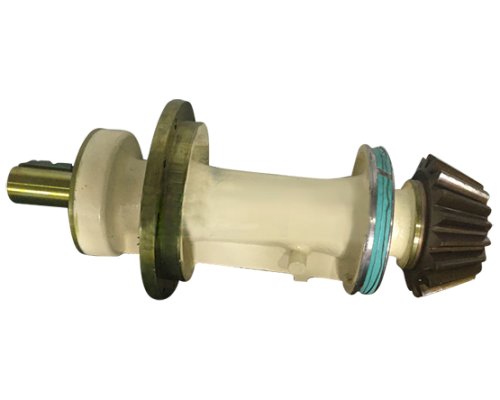

the components of crusher | plastic bottle crusher for recycling

Components of Jaw Crushers - johnheineau's diary. Aug 17, · Components and Parts of Jaw Crushers. To run the Jaw crushers, it involves two main components such as brackets, the pitman, and the sheaves. These are jaw crusher parts that produce the smashing action and give the energy necessary to crush the rocks.

Learn More

Design of Used PET Bottles Crushing Machine for ... - DergiPark

The global PET packaging market was worth $48.1 billion in , amounting to almost 16 million tons according to a new market report. Demand

Learn More

Pet bottle recycling project report pdf - vnbg.atbeauty.info

And, for every 1 ton of plastic that's recycled, reports estimate that 7 yards of landfill space is saved. By recycling, you can also help conserve the additional 80% of energy that's typically used when making new plastic bottles, containers and other items instead of recycling. It's easy to see why recycling plastic is so important.

Learn More

PDF Design And Construction Of A Plastic Shredding Machine - JMESTPDF

The plastic shredding machine crushes used plastic bottles and helps in municipal waste management and disposal. The machine is designed using locally available raw materials which make it cheap and easy to maintain and repair. The performance test analysis carried out defines the characteristics of the machine and

Learn More