me mill liners

mill liner for sale, mill liner of Professional suppliers

OHSAS18001 Mn18Cr2 Low Carbide Steel Grinding Ball Mill Liner Mill Shell Liner End Liner Grate Liner Grind Lining Product Description: Cast grinding ball mill liner, Mill liner plater, Ball Mill wearing plater, wear plate: A. Chrome Alloyed Ball Mill Liner Plates B. Chromium-Molybdenum Alloyed Ball Mill Liner Plates C. High Manganese Steel Ball

Learn More

Mill linings - Element

Medium-carbon alloy martensitic steel with a chromium content of. 5%, nickel, 0.8%, and molybdenum, 0.8%. Linings made of this steel have high hardness in

Learn More

Jay paper mill to close in early 2023 - Portland Press Herald

Submitted photo. JAY — The Androscoggin paper mill, which employs about 230 people and is the town's biggest private employer, will close in the first quarter of 2023, according to the company

Learn More

Evaluation of Abrasive Wear Measurement Devices of Mill

Mill Liners, Wear measurement, Mining, Mills, Measurement devices, Evaluation, Quality index. 1. INTRODUCTION. Mills used in the mining industry and ore.

Learn More

Castings & Liners - Compatible with Warman® and ® Mills

This leads to increased mill efficiency while prioritizing worker safety. Check out ICS-200 for a quick fix. Available Types. Sag Mill Liners; Ball Mill

Learn More

Ball mill liner - Wear Parts For Industry | Qiming Casting

Ball Mill Liners By Qiming Casting® Ball mill liners are the main replacement wear parts for ball mills. These liners are manufactured by wear-resistant material and rubble. As a wear-resistant foundry, Qiming Casting manufactures manganese steel, Cr-Mo alloy steel, and Ni-hard steel liners for all kinds of ball mills, which include: single wave liners, modified single wave liners,

Learn More

Mill liner wear and performance monitoring - Outotec

3D DEM simulations. MillMapper™ is the patented industry standard in mill liner condition monitoring and 3D modeling. You get full analysis on all visible surfaces. From every scan, over

Learn More

SAG Mill Liner Design - Mineral Processing & Metallurgy

Based on experience, mill-liner designs have moved toward more open-shell lifter spacing, increased pulp lifter volumetric capacity, and a grate design to facilitate maximizing both pebble-crushing circuit utilization and SAG mill capacity. As a guideline, mill throughput is maximized with shell lifters between ratios of 2.5:1 and 5.0:1.

Learn More

Mill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

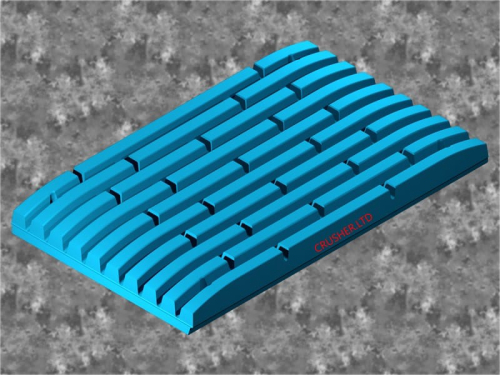

Mill Liners The mill liner is installed inside the ball mill barrel to protect the inner wall of the barrel from the impact of materials and grinding media ( steel balls, steel sylpebs, steel rods, etc .) to avoid premature damage to the barrel.

Learn More

How to Replace the Ball Mill Liner?

Could you please send me some extra information about replacing liner? Like Sign in to like this comment. Reply

Learn More

Mine Mill Liners % Mill Liners - EB Castworld

The general advantages in Mine Mill Liners are as follows: In the recent 20 years, our liners have been widely used in large,medium and small ball mills in Chinese power generation, mining, cement, chemical engineering and metallurgical industries and super fine pulverizing equipments. It is the only recommended liner productin the latest

Learn More

Mill Liner/ We are More Professional - EB Castworld

Mill liner design in relation to total mill weight: Weight has a great impact on the process, so it needs to be considered in utilizing the maximum capacity of the grinding mill. The theoretical capacity is mainly based on volume of the mill, installed power and structural strength of the mill. The mill structure and bearings can handle a

Learn More

RME · MILLMAST MAX - Russell Mineral Equipment

The MILLMAST MAX Mill Liner Handler is an efficient relining solution for Ball mills with liners up to 400kg and sufficient free space at one end of the mill. By removing the need for manual lifting, MILLMAST MAX delivers an affordable and reliable way to boost productivity and crew safety. Available for Ball mills up to 26ft in diameter. Minimum clear entry diameter is 1150mm.

Learn More

Jay paper mill damaged in blast will close for good

PUBLISHED 5:27 PM ET Sep. 20, 2022. The paper mill in Jay will close early next year, putting about 230 people out of work, Pixelle Specialty Solutions announced Tuesday. The mill, the site of an explosion in that destroyed the mill's digester, will close because of financial instability. "Economic forces beyond our control have

Learn More

SAG Mill Liner Design - 911 Metallurgist

Grinding Mill Shell Design; Semi-Autogenous Mill Liners Designs Alloys and Maintenance Procedures M-E patented Wedgit feature.

Learn More

Mill lining solutions for horizontal mills - Outotec

With Outotec mill lining solutions, we help you mills and liners, so we know how to get the most from your 1 Outo tec. Broc.

Learn More

Design improvements extended life of SAG mill liner

Due to a modified design that ME Elecmetal implemented, it was possible to increase the wear life of the shell liners for a SAG mill, increasing from 4.5

Learn More

What is a ball mill liner? - Quora

Several grinding mill liner users have complained that the liners of a ball mill have a short service life and a high production cost. Let me quickly mention

Learn More

3 Reasons and 4 Improvement Measures for the Wear of Ball Mill Liner

3 reasons of the wear of the ball mill liner. Firstly, the wrong installation method will lead to insufficient concentration of the lining plate, which leads to rupture; Secondly, the raw material

Learn More

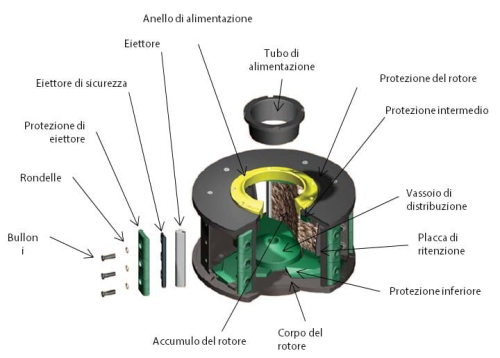

Mills & Mill Liners

Mills and Mill Liners. Crushers & Equipment International Limited can supply new Ball mills and rod mills to your specific request. From 4' diameter to 18' diameter. These can be overflow or grate discharge, supplied with the following liners: Crushers & Equipment offer a range of mills tailored to your needs.

Learn More

Ball mill liner | Magotteaux

The role of a ball mill liner is to give the mill heads protection against wear and tear thus increasing their lifetime and creating optimal grinding

Learn More