shock pulse monitoring and vibration analysis

AN INTRODUCTION TO THE SHOCK RESPONSE SPECTRUM

Figure 5 shows the shock response spectrum corresponding to the example in Figure 4. 2 In contrast, the level at a center frequency in a random vibration power spectral density represents the average mean square level across the band. 3 Another shock response spectrum format is based on the relative displacement of the mass. An

Learn More

What is Vibration Analysis? - CBM CONNECT

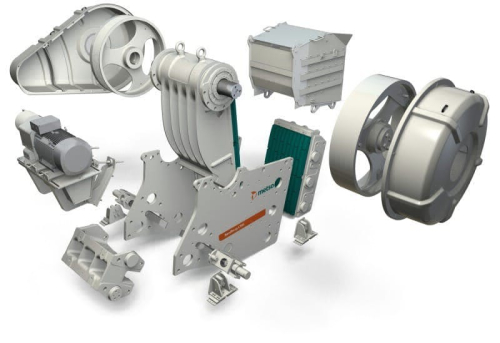

Industrial vibration analysis refers to a process for measuring the vibration levels and frequencies of machinery and then using this information to assess the "health/condition" of the machine and its components. Shock Pulse Monitoring When two pieces of metal touch each other while in motion, stress waves develop from the impact which

Learn More

Shock pulse measurement on the fan in 9 days before

Vibration analysis and the Shock Pulse Method (SPM) are two of the most popular condition monitoring techniques used in Condition-Based Maintenance (CBM)

Learn More

Comparison between Shock Pulse Method and Vibration

In this paper, the vibration analysis methods and shock pulse method (SPM) are compared in order to detect the unhealthy condition as well as fault type in

Learn More

PDF Shock Pulse and Vibration Monitoring

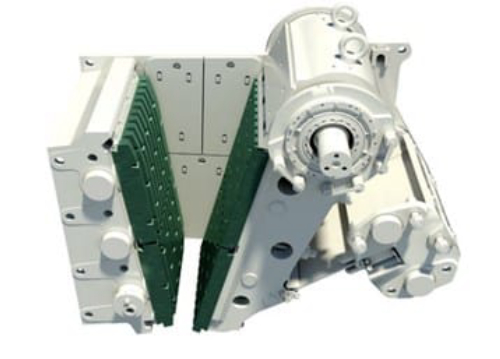

The combination of vibration and shock pulse measurement is ideal for monitoring mine hoist performance. The shock pulse technology is very suitable for detection of bearing damages in typical industrial environments, while vibration technology is optimal for low frequency-related fault conditions like unbalance, loose gears and misalignment.

Learn More

Vibration Analysis & Shock Pulse Monitoring for Thermography Inspection

Vibration & Shock Pulse analysis - The benefits The bottom line is that vibration analysis benefits both the operator and the maintenance technician: Enables the identification of machine faults Provides information on causes Localizes the affected components Optimizes spare parts logistics Allows early planning of maintenance measures

Learn More

enDAQ Shock & Vibration Sensors for Shipping Monitoring | Resources

Get the most complete picture of your valuable package's journey with an enDAQ shock and vibration recorder. enDAQ's vibration sensors and loggers offer a configurable, accurate and reliable solution for gathering data with accelerometers. These devices include two embedded accelerometers to provide a wide dynamic range to capture low amplitude

Learn More

An Introduction SPM HD Method

A comparison with vibration enve- loping techniques is made as well. 2 The Shock Pulse Method. 2.1 Shock pulses. Shock pulses are elastic waves propagating in “

Learn More

Shock pulse monitoring - SPM Instrument

Shock pulse monitoring Shock pulse monitoring SPM is an abbreviation for the Shock Pulse Method, which is a patented technique for using signals from rolling element bearings as the basis for efficient condition monitoring of machines. Instant evaluation of bearing condition is given in an easily understood green-yellow-red color scheme.

Learn More

Vibration Analysis & Shock Pulse Monitoring for

Shock pulse analysis. When a bearing has a lubrication problem or an incipient failure, it starts to emit ultrasound. Historically, the structure-borne ultrasound generated inside bearings and

Learn More

Condition Monitoring - Professional Control Corporation

The module collects the two most important parameters for machine condition analysis: Vibration Velocity and Shock Pulse. 750-645 Vibration Monitoring

Learn More

Measuring Shock Pulse another approach to Front Line

If the philosophy of front line Condition Monitoring is utilized, shock pulse measurements would be utilized as the first stage of identifying anomalies.

Learn More

Shock and vibration data logger - Wikipedia

Shock and vibration logger with integrated 3-axis digital accelerometer and lithium-polymer battery. A shock data logger or vibration data logger is a measurement instrument that is capable of autonomously recording shocks or vibrations over a defined period of time. Digital data is usually in the form of acceleration and time.

Learn More

Shock Pulse monitoring - CBM CONNECT

Shock Pulse monitoring Industrial vibration analysis refers to a process for measuring the vibration levels and frequencies of machinery and then using this information to assess the “health/condition” of the machine and its components. is designed specifically for condition monitoring professionals, maintenance managers and

Learn More

Shock Pulse Monitoring - Process & Power

Unless an individual is involved with some form of machinery vibration analysis, the term "Shock Pulse" (Monitoring) is unknown and somewhat foreign.

Learn More

Condition Monitoring Techniques - What is Shock Pulse Monitoring (SPM)?

Shock Pulse Monitoring also known as SPM is a patented technique of predictive maintenance by measuring vibration and shock pulses of bearing in motors and to identify their condition and operating life before the next overhaul procedure.

Learn More

What is Vibration Analysis and Shock Pulse Monitoring? - Elite Thermography

Benefits of Vibration Analysis and Shock Analysis: Determine structural or rotating looseness or the presence of resonance Check bearing concentricity Detect misalignment or imbalance Establish your Repair Priorities based on the results Improve Your Preventive Maintenance Quality and Results Test Under Load without any planned shutdown

Learn More

Reliability: Improve condition monitoring with shock pulse

Shock pulse technology is generally well known to vibration analysts and reliability technicians. A handheld combination of sensor and display meter would

Learn More

Vibration analysis on a bearing using shock pulse measuring

Vibration Analysis on a Bearing Using Shock Pulse Measuring. Techniques Monitoring the performance of the bearing is then important to.

Learn More

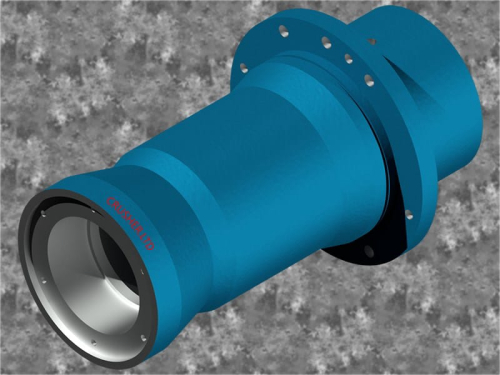

Vibration monitoring - SPM Marine & Offshore

We offer advanced vibration monitoring techniques for early detection of a wide variety of mechanical fault conditions such as unbalance, misalignment, resonance, looseness, and faulty gears or bearings on all types of rotating machinery. Machine vibration monitoring is the most widespread method to determine the health of rotating equipment.

Learn More

SPM Monitoring - Toowoomba Bearings & Hydraulics

Shock Pulse Method, which is a patented technique for using signals from rotating rolling bearings as the basis for efficient condition monitoring of

Learn More