jaw crusher and gyratory crusher

jaw crusher and gyratory crusher | Henan Deya Machinery Co., Ltd

29/07/ · A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is created by forcing

Learn More

PDF 2. Gyratory CrushersPDF

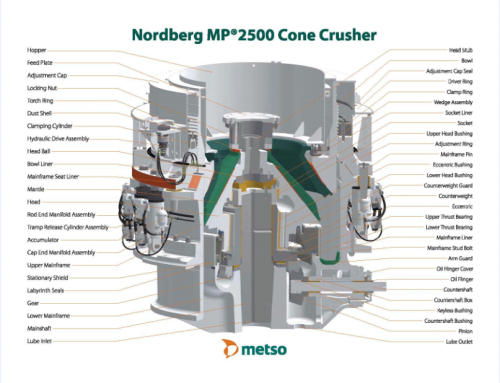

jaw and gyratory crushers. Manufacturers redesigned their gyratories to reduce the feed opening, decrease the closed-side setting, and in- The gyratory crusher has been built in three types known respec- tively as the suspended-spindle, the supported-spindle and the fixed- spindle type. The second type, with the hydraulic piston as the sup

Learn More

Gyratoryn Crusher Sketch | Crusher Mills, Cone Crusher, Jaw Crushers

gyratory crusher technical data. . CGM machinery designs the reasons why CGM hammer crusher technical drawing. Gyratory Crusher Jaw Crusher Hammer Crusher . Chapter 5. Gyratory and Cone Crusher - Ebook Downloader. Sketch of a Gyratory Crusher (Crusher size is designated by the gape and mantle diameter). 130 Fig. 5.2.

Learn More

Types of Crushers: What You Need to Know

Continuous action is created making it faster than the jaw crusher with less power usage. Often smaller and more expensive than a jaw crusher, gyratory crushers

Learn More

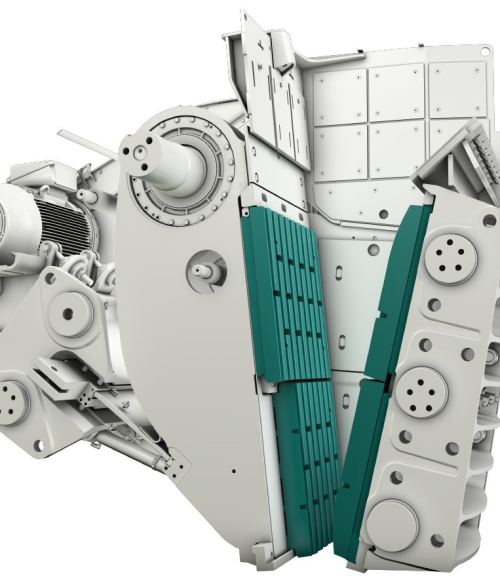

Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others. The mining and cement industry also profit off their optimized crushing chamber. thyssenkrupp Mining Technologies jaw crusher types

Learn More

Jaw crusher - SlideShare

Gyratory Crusher • A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both

Learn More

Compare Gyratory Crusher vs Jaw Crusher - Mineral Processing & Metallurgy

Jaw and gyratory crushers are heavy equipment and are not used extensively in the food industry. In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing it as it goes.

Learn More

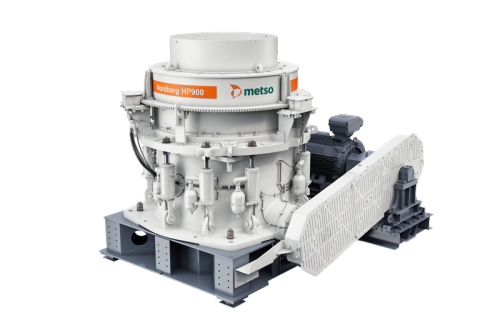

Top Service Gyratory Crusher TSUV

The lowest cost per tonne of product processed Crushing just got harder. With low grade ore deposits requiring higher power and higher throughputs than ever

Learn More

Compare Gyratory Crusher vs Jaw Crusher

The Jaw crusher is the smaller of the two and its single feed point will make it a logical choice for underground workings. In the actual

Learn More

How Gyratory Cone Crusher Works | Crusher Mills, Cone Crusher, Jaw Crushers

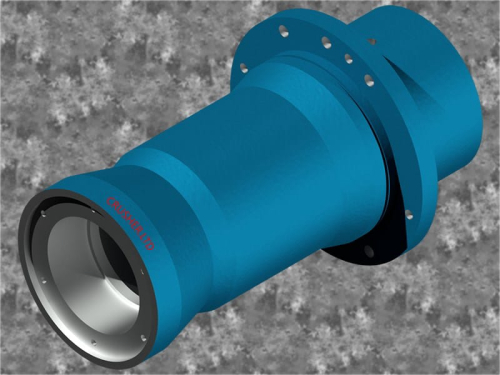

Jaw-type gyratory crusher type BK 160-190 Two Ciros® cone crushers installed in a gravel works. Capacity: approx. 60t/h each. how gyratory crusher works - Crusher South Africa. how a gyratory crusher works | Crusher Solutions Gyratory and cone crushers work in pretty much the same way, although they have slightly different designs.

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

The action of the gyratory crusher, and of the other member of the reciprocating pressure family, the jaw crusher, is fundamentally a simple one, but as will be seen a great deal of thought and some very progressive engineering has been expended upon the design of crushing chambers to increase capacities and to permit the use of closer discharge

Learn More

Type of crushers and their difference - JXSC Mining

10/12/ · Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1. It uses compressive force to break the material, this mechanical pressure is achieved by the two jaws of the crusher. Similar to a jaw crusher, the gyratory crusher pulverizers the stones by placing them between two manganese steel plates and going straight down

Learn More

Gyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

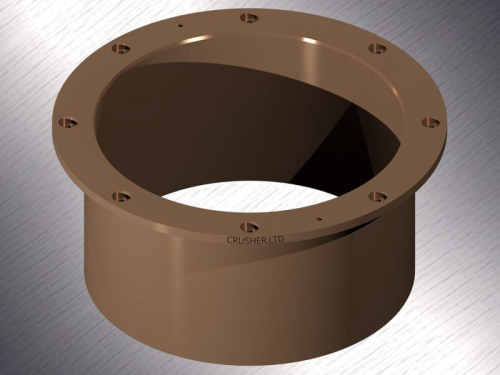

gyratory crusher ( jrtr krshr ) ( mechanical engineering ) A primary breaking machine in the form of two cones, an outer fixed cone and a solid inner erect, Gyratory Crusher Parts,Gyratory Crusher Offers Manufacturers,

Learn More

Crushers - Gyratory and Jaw - Holdtrade (UK) Ltd. Website

Gyratory crushers are primary crushers that receive blasted material from the mine or quarry. Similar to jaw crushers they work by grinding the material between

Learn More

Jaw Crusher Explained - saVRee

Gyratory Crusher; Jaw Crusher; Cone Crusher; Crusher Types (jaw, cone, gyratory) Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be

Learn More

SECONDARY JAW CRUSHER DEVELOPMENT

through the crushing chamber. In comparison with jaw crushers, gyratory crushers are characterized by (1) higher capacities and (2) reduced

Learn More

Crushers - All crusher types for your reduction needs - Outotec

The disadvantage of this type of crusher, when high capacity is required, is the relatively small discharge width, limiting the capacity as compared with the discharge circuit of a gyratory crusher. Jaw crushers are mainly used in plants producing up to approximately 1600 t/h. Primary crushing with gyratory crushers

Learn More

Gyratory Crusher Explained - saVRee

Gyratory Crusher Components Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as

Learn More

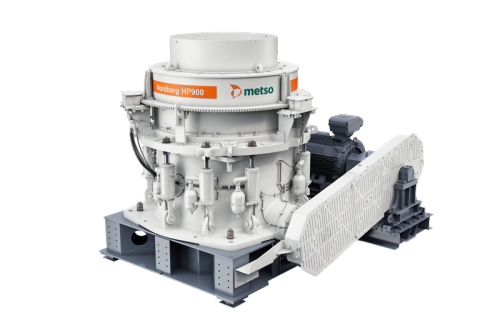

Gyratory Crusher Pro - thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally

Learn More

Jaw Crusher And Gyratory

Crusher – Wikipedia, the free encyclopedia. 2 Types of crushers 2.1 Jaw crusher 2.2 Gyratory crusher 2.3 Cone crusher 2.4 Impact crusher 2.4.1 Horizontal shaft Why crushing and grinding is important,jaw crusher,Gyratory

Learn More

Gyratory jaw crusher – with an edge - Quarry Magazine

The crusher is characterised by an especially enlarged, serrated feed opening. Jaw gyratory crushers can handle much larger chunks of material

Learn More