jaw crusher installation

Jaw Crusher Installation Guidance | Mining, Crushing, Grinding

Jaw crusher is a large-scale mining machinery and equipment. It not only used in mine mining, but also used such in stone crushing, construction waste, which is also occupy this important position, so it is important to use large equipment must pay special attention to prevent improper use of efficiency reduce equipment wear and tear, or even life-threatening condition occurs.

Learn More

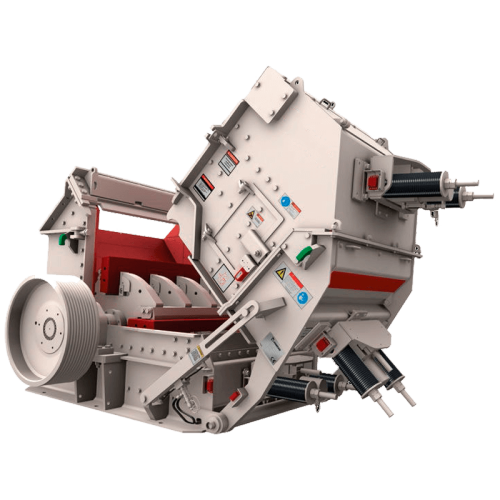

Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

Simple installation due to compact design with integrated drive motor Fields of application Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others.

Learn More

Jaw Crusher Installation Manual | Crusher Mills, Cone Crusher, Jaw Crushers

Instructions on Installation and Test Run of Jaw crusher The manipulation regulations of jaw crusher: 1 Abide by Henan casting equipment manipulation regulations. 2 Check the tightness of V-belts and wear condition. I. II. III. IV. Installation, debugging and trial operation operate according to the manual.

Learn More

Jaw Crusher BB 600 XL - Retsch - Solutions in Milling & Sieving

Due to the low installation height of 1 meter the BB 600 is ideally suited for continuous operation in automatic installations and sampling stations. Thanks to

Learn More

Installation of Jaw Crusher | Skills and Notes - JXSC Mine

The movable jaw of the jaw crusher is assembled by preassembled movable jaw parts. First, Assemble the movable jaw parts accordingly. The movable jaw, movable

Learn More

Fisher Industries Crusher Operator Job in Livingston, MT | Glassdoor

Livingston, MT. $38K - $49K ( Glassdoor est.) Easy Apply. Job. Salary. Company. Rating. Fisher Industries is a family of businesses that encompass all aspects of the aggregate production and heavy civil construction industries. Our unique, vertically-integrated business model allows us to handle small projects, large scale operations, and every

Learn More

C Series™ jaw crushers - Corporation - DirectIndustry

Pinned and bolted, non-welded frame construction Save time and costs Minimize on-site engineering Install easily Modular design enables easy installation C Series jaw crushers are modular for quick, easy installation and commissioning in new plants and when replacing old jaw crushers.

Learn More

Aggregate Crushers - High-efficiency And Eco-friendly

In this configuration, we equip two mobile crushers in it. One mobile crusher equips with an APG-4211W vibrating feeder and an APJ-7510E jaw crusher, and another one is equipped with an APC-200C cone crusher and an APS-2160Y4 vibrating screen. Corresponding Requirements: It can be used to crusher hard rocks to produce aggregate for various fields.

Learn More

Jaw Crusher Installation Points_The NIle Machinery Co.,Ltd

The jaw crusher is usually installed on a concrete foundation with a drain tank on the foundation. The slope is less than 50 degrees. Since the vibration of the

Learn More

C series jaw crusher Manual - SlideShare

A good example is the optional intermediate plate that is installed behind the fixed jaw for occasions when you need to change the nip angle.

Learn More

Jaw Crusher Manual

It is suggested to install the equipment on concrete base to decrease vibration, noise and absorption of shock and avoid impact on building base. Fill ironwood,

Learn More

Jaw Crusher Handbook | Stone Crusher PDF - JXSC Mine

Installation and Adjustment 1. The crusher is installed on the pre-made Foundation (the foundation should be well laid), the crusher finds a good level. The base plate and the foundation are left about a 20mm gap filled with cement mortar. Then tighten the nut of the base bolt when the mortar stiffness.

Learn More

Jaw crushr operate manual: how to install, repair and examine it

Jaw crushers are usually installed on concrete foundations, with a drainage trough reserved for the foundation, preferably with a slope of less

Learn More

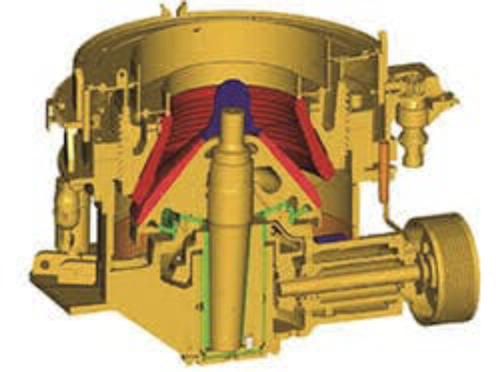

Below the surface: Setting up an underground primary jaw crusher

2014. 4. 1. · Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

Learn More

Crushing, screening, feeding and plant solutions

greater throughput/higher reduction) after installation. Maintenance. The TS gyratory crusher is distinguished from other gyratory.

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Learn More

jaw stone crusher installation manual pdf

jaw stone crusher installation manual pdf technical guide on jaw crushers worldcrushers Crushers All crusher types for your reduction needs Manual Stone Crusher

Learn More

Jaw crusher installation fine jaw crusher #jawcrusher #crusher

Jingying Machinery is the factory with over 30 years experience for the stone crusher line (stationary crushing line or mobile crushig line). Give me more de

Learn More

Stationary jaw crushers - rockprocessing

The wide range of jaw plates can be mixed and reversed to ensure optimal, versatile crushing. EASY TO SET UP AND INSTALL. When you order from you order

Learn More

Jaw Crushers - Parker Plant

Parker have been engineering rock crushers for over 100 years and today thousands of jaw crushing machines and units have been installed around the world.

Learn More

What is a Jaw Crusher | Advantages, Types, Parts and

The movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the crushed material passes through the discharge port in

Learn More