crusher safety

Improving jaw crusher safety | WEG

7/15 · /07/15 According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to

Learn More

Crusher inspections - Outotec

More thorough and specialized inspections should then be conducted by Outotec experts. 1000-hour Operating Inspection: up to two hours with the equipment operating and about 4-6 hours shutdown depending on whether it's a stationary or mobile operation to review general condition of equipment. This includes a review of key wear

Learn More

Ball Crusher Toy Safety - Body Jewelry & Piercing Blog | The Chain

8/17 · In order for a ball crusher to be safe it needs to have a proper design that is made for pain and pleasure but that also ensures safety. Also, it is vital that people use this toy with caution. Ball crushers are specially designed to provide very

Learn More

Crusher Safety - Safety Training PowerPoint Presentations

For more information on using Translator with Microsoft PowerPoint, visit here . Category: Crusher Safety. View all files in this category. 6 slides. Crusher Fatality. Fatal accident

Learn More

Crushers - an overview | ScienceDirect Topics

Rotary bottom crusher. The main manufacturing steps are as follows: • Site selection and separation • Weighting and control • Fragmentation • Primary crushing • Steel separation by magnetic means • Manual separation of plastic, wood, and paper • Secondary crushing • Sieving View chapter Purchase book

Learn More

HSE - Quarries - Safe operation and use of mobile jaw crushers

The crusher should be shut off and isolated before considering the use of bars and hand hammers. Careful consideration should be given to the risk of large pieces of feed material moving and

Learn More

7 Crusher Equipment Safety Tips - Multico Prime Power Inc. Philippines

These crusher safety tips will prevent accidents in the workplace, maintain functioning equipment for a long time, and increase productivity. The key here is to prioritize training your operators so they know how to wear protective clothing, work within a crusher's capacity, maintain it, and keep the area clean.

Learn More

Guideline-Management-Crushing-and-Screening ... - Minex NZ

WITH CRUSHING AND. SCREENING PLANT. Updated February 2010. NOTE: These guidelines have been superseded by the Health and safety at opencast mines,

Learn More

New crusher improves quarry efficiency and operator safety

12/13 · New crusher improves quarry efficiency and operator safety. QI353 impact crusher has been built with more productivity, connectivity and safety at the forefront of its innovative design. has launched a new crusher, QI353, which is the most versatile, mid-sized mobile impact crusher available on the market.

Learn More

Mobile Concrete Crusher SWMS | SafetyDocs PDF & Word Templates

This Mobile Concrete Crusher Safe Work Method Statement covers hazards and controls associated with the operation of concrete crushers being loaded by an excavator. This SWMS covers High-Risk Construction Work (HRCW) controls related to: Mobile plant movement. Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines

Learn More

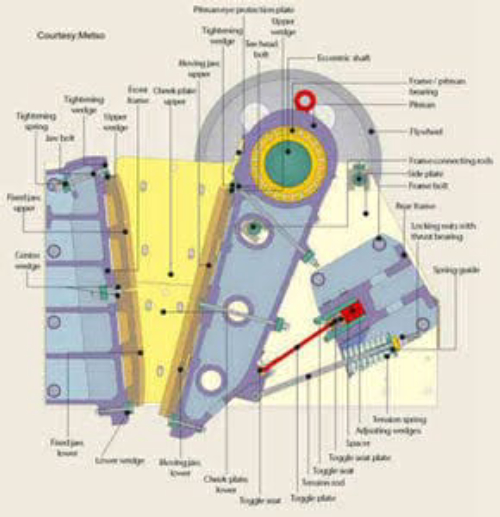

US3511444A - Safety device for jaw crusher - Google Patents

It is known to provide safety devices such as safety toggles which are intended to fail at a predetermined overload force on one of the crusher jaws. Most of

Learn More

Crusher-Safety — SAGE MANAGEMENT

SERVING THE AGGREGATE INDUSTRY FOR OVER 40 YEARS SAFTEY Sage Management is COR certified, fully bondable and WCB insured. Sage Management also has a fantastic record

Learn More

Top safety tips for working around crushing and screening

Crushers will continue to rotate slowly during their coast-down time, which creates a potential safety hazard - all personnel must stay clear of

Learn More

The Importance of Hopper Feeder Safety When Crushing

This article does not serve as an official safety recommendation by and should not be viewed as such. All relevant staff should

Learn More

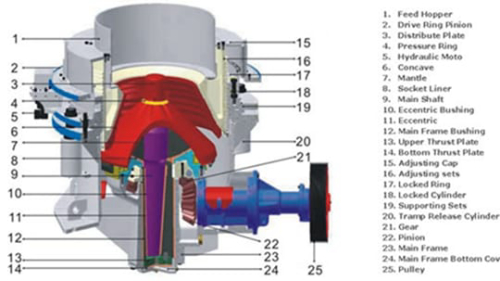

Top service TSUV Gyratory Crushers Safer, smarter and more powerful crushing

TSUV Gyratory Crushers Safer, smarter and more powerful crushing WE DISCOVER POTENTIAL Digital solutions to ENAL power your productivity FLSMIDT T 3 0 1990 Cu Concentrator throughput (kTPD) % Copper 1995 2000 2005 2025 0 0.2

Learn More

Safe Job Procedures For Crusher Operations

The following is about roller crusher safe work procedure. 1. Shut off the crusher and standard operation maintenance procedure of coal crusher procedures. 2. For the coal mill to work there should be equipment "Maintenance of the safe operation JAW CRUSHER OPERATION AND MAINTENANCE safe operating procedures stone crusher

Learn More

safety operation of crusher

safety operation of crusher Crusher Wikipedia. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. . Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with . The safety cylinder of the machine can ensure safety as

Learn More

CONVEYOR & CRUSHER SAFETY - ppt download

7 Best Practices SLAM Risks (Stop, Look, Analyze, and Manage). Establish and discuss safe work procedures. Identify and control all hazards. Ensure the job is

Learn More

Five Basic Safety Rules To Follow When Using An Impact Crusher

Below are five basic safety rules to follow when using an impact crusher to help keep accidents or injuries from occurring. AIMIX Impact Crusher 1. The only people who should work with or near the crusher are people who are properly trained. Workers without adequate training or experience should avoid the impact crusher altogether.

Learn More

Cone Crusher Safety And Maintenance | Crusher Mills, Cone Crusher, Jaw

Cone Crusher, Ores and Rocks Crusher for sale -Ball Mill. cone crusher series easy maintenance, convenient chamber so as not to damage the cone crusher. The safety system uses dry oil and water as two

Learn More

PDF Sand, Gravel, and Crushed Stone On-the-job Training ModulesPDF

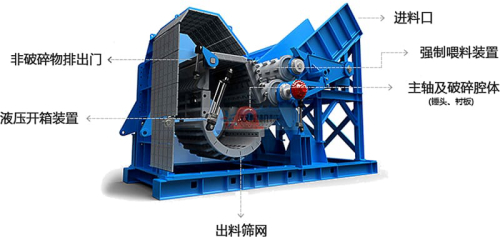

by a secondary crusher, and sometimes a tertiary crusher. Raw material, of various sizes, is brought to the primary crusher by rear-dump haul units, or carried by a w heel front- end l oader . Pr imar y cr ushi ng reduces thi s run- of -mine r ock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory

Learn More