ball mill liners

Mill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

The mill liner is installed inside the ball mill barrel to protect the inner wall of the barrel from the impact of materials and grinding media (steel balls, steel sylpebs, steel rods, etc.) to avoid

Learn More

Elastic polyurethane Mill liners - Eurogomma

Elastic polyurethane Mill liners · Polyurethane Lifter bars · Polyurethane Shell liners · Polyurethane Head liners and grates.

Learn More

ball mill rubber liner

The rubber liner plate for ball mill cansatisfiedthe overflow type,grid-type and multi-chamber ball mill type. The maximum specification with wear-resisting rubber lining board of ball mill is Φ5500X8850. It has been used in the field of black metal mines,non-ferrous metal mines,chemical mines,golden mines and steel smelting,nonferrous metal

Learn More

Linex Bed Liner in Hillsboro, OR with Reviews - YP.com

Find 4 listings related to Linex Bed Liner in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for Linex Bed Liner locations in Hillsboro, OR.

Learn More

Ball Mill Linings | Multotec

Ball Mill Linings from Multotec provide optimum wear lining solutions for the toughest applications, ensuring optimum grinding and crushing efficiency.. Blinding of grate plates is

Learn More

Pool Liners in Hillsboro, OR | Call 888-670-2217

Pool Liner Authority has different types of Pool Liners in Hillsboro, OR.Overlap Pool Liners in Hillsboro, OR extend over the wall of a swimming pool and are folded along the edge, then secured inside the swimming pool below the top rail.. This type of pool liner is very popular in Hillsboro, OR since installation is relatively simple and the liners are less expensive than the more decorative

Learn More

Ball Mill Liners - Vulcan Sanat

Ball mill liner. The ball mill are a special kind of grinding machine, in this machine the media balls along with the solids materials are placed in a

Learn More

Double Wave Ball Mill Liners - EB Castworld % Ball Mill Liners

Characteristics of Double Wave Ball Mill Liners. ⒈High wear resistance and impact resistance The alloy steel liner in dual-medium quenching is scientifically and reasonably formulated with alloy elements, so that the liner has good physical and chemical properties. The hardness is above HRC45-55, the impact toughness is above 25J, and the

Learn More

liners crusherball liners mill -- earna

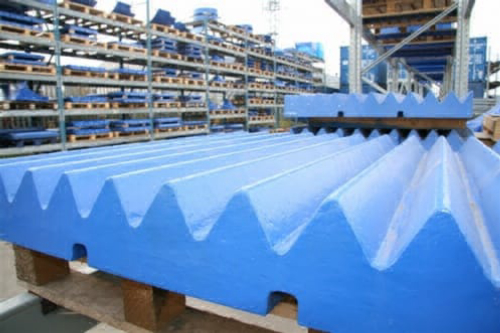

Ball Mill Liner Design Mineral Processing amp Metallurgy. Jan 05, The liners are from 50 to 65 mm thick (2″ to 2.5″) with the waves from 60 to 75 mm (2.5″ to 3″) above the liners.

Learn More

Ball Mill / SAG Mill Steel Shell Liners - Unicast Inc

Ball Mill / SAG Mill Steel Shell Liners Unicast Shell Liners are cast in materials ranging from chrome-moly steels to high chrome white iron. A minimum

Learn More

Ball Mill Liners on sales - Quality Ball Mill Liners supplier

Boltless Ball Mill Liners Grinding Mill Power Plant / Ball Mill Parts Industry Grid Cement Mill Liners Wear Resistance With ZGCr5Mo Hardness AK5-15J High Abrasion Steel Mill Liners Standard AS 2027 CrMo 15 / 3 Ball Mill Liners (51) Large Martensitic Cr-Mo Alloy Steel 95 - 107 Hammer Crushers OEM Contact Now

Learn More

Rubber Ball Mill Liner - Strudex Mining

The ball mill liners' material and shape are different base on requirements. When the grinding media contacts with different shapes of ball mill liners, the movement state will also change, thus enhancing the crushing effect on the material. This design of the mill liners effectively improves the grinding efficiency of the ball mill machine

Learn More

3 Reasons and 4 Improvement Measures for the Wear of Ball Mill Liner

24/06/ · The liner plays a decisive role in the quality of the ball mill.Its main role is to prevent the cylinder from wearing, it is also the easiest part to be worn. 3 reasons of the wear of the ball

Learn More

Steel Ball Mill Liners

In Φ2.2 x 6m ball mill, the capacity is 3.2mt per hour on 2μm∼10μm, which has achieved leading level at home and abroad. In 2000, we designed the first set of the boltless liners applied in a

Learn More

Home [ballmillrubberliner.com

This product is an important part for conical ball mill and its call "feed end liners for ball mill' its main function is to protect the end cover of ball mill. The high wear-resistance head liner Read More . SIDE WALL CIRCLE. This product is also call blind disk for Ball Mill. It is a round plate which has all of the relevant bolt holes but

Learn More

Ball Mill Liners - China Manufacturers, Suppliers, Factory

Ball Mill Liners - China Manufacturers, Suppliers, Factory Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for Ball Mill Liners, Cr26 hammer head , Mining Equipments Parts , Cheek Plate Liner Bolt , Hammer Hear for Crusher .

Learn More

The Different Types of Mill Liners You Should Know

All ball mill liners must be very resistant and capable of withstanding high impacts. The milling process uses steel balls to break down the

Learn More

Ball Mill Rubber Liners - 5 pallets - D'Angelo International

Rubber Lining Materials - 5 pallets. Ball Mill Rubber Liners - 5 pallets 5 pallets of rubber liners for a mill 13 head liners. - 1,400 lbs.

Learn More

When to change ball mill liners? - Qiming Machinery

The ball is the fundamental component of the mill liner, which ensures the proper grinding process. Unless you have used a different and harder material, if the grinding process slows down or yields lesser output as compared to normal, it may be an indication that your ball mill liners may need a change because they may be internally damaged.

Learn More

Ball Mill Liners Material Selection And Application

The ball mill liners and grinding media are the largest consumption of wear-resistant iron and steel parts with an annual consumption of 2 million tons in China. With the development of China's economic construction, the demand for cement is increasing year by year, and the consumption of wear-resistant materials is also increasing

Learn More

SAG and Ball Mill Liner - EB Castworld

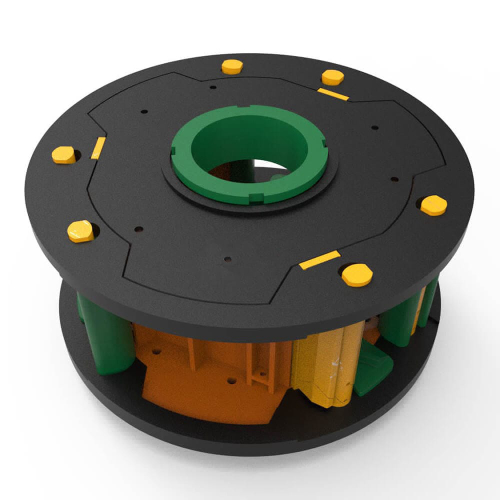

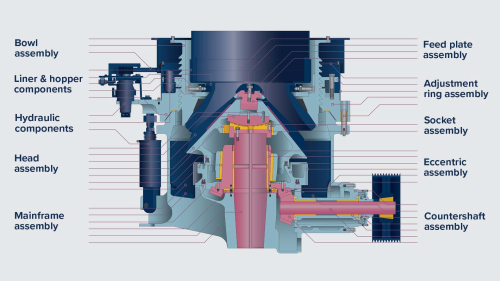

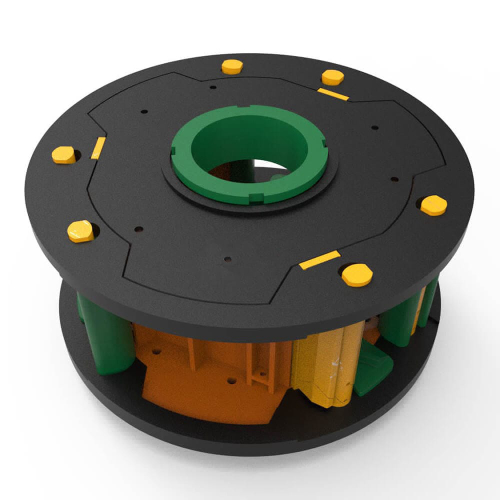

SAG and Ball Mill Liner system serves two purposes: Protect the mill shell from wear caused by the impact and abrasion of the mill charge, and to elevate and tumble the mill contents in the necessary manner to create a grinding action. To achieve this, the mill liner profile must be constructed from high wear resistant materials and incorporate correct geometry to help determine the elevation

Learn More