planetary gearbox design

DESIGN AND CALCULATION OF PLANETARY

Abstract: In this paper, the design and calculation of planetary transmission with bevel gears for road vehicles is presented. It must transfer power to the

Learn More

Planetary Gear Design - Thomasnet

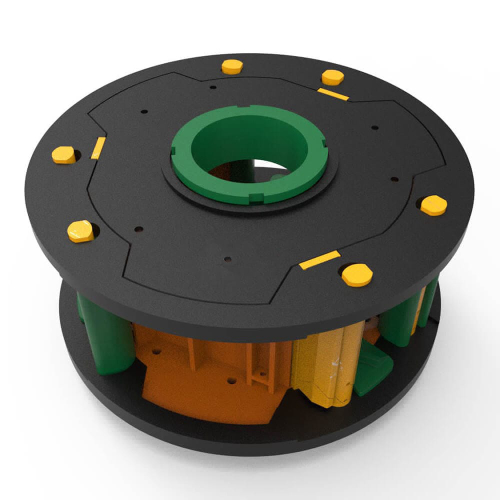

A planetary gear system, also referred to as epicyclic gearing, consists of three elements – a sun gear, one or more planet gears, and a ring gear.

Learn More

Planetary Gearbox for Bar Bending Machine | Industrial Gearboxes

The Planetary Gearbox series for bar bending is designed in such a way that, the torque generated by the gearbox is sufficient enough to bend the bar of dia. 12 mm to 48 mm easily. Top Gear designs a special planetary gearbox with a hollow output shaft with a single or double keyway so which the banding wheel of the machine is attached.

Learn More

Planetary gears — A review of basic design criteria ... - Machine Design

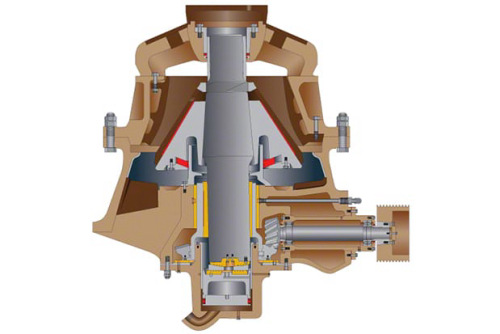

Jan 19, · A planetary gearhead takes a high-speed, low-torque input, say from an electric motor, then increases torque and reduces speed at the output by the gearhead ratio. This lets motors run at higher,

Learn More

How to I design a planetary gear with a gear ratio of 2:1

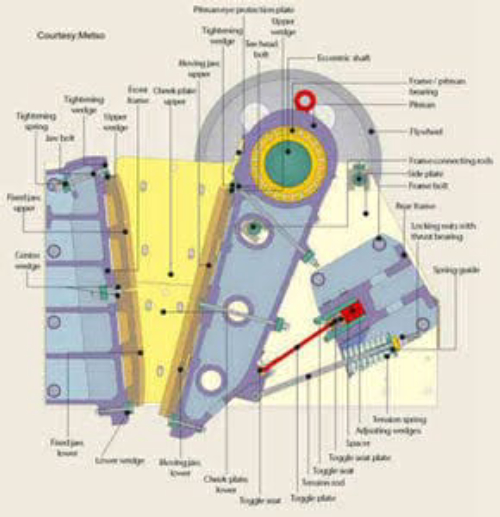

Image from Wikipedia) When designing planetary gears, there are three different types of gear present to be designed: • Annulus gear, an internal

Learn More

Planetary gearboxes - BJ-Gear: Gear and transmission solutions

The planetary gearboxes with output flange have a design that is suitable for combination operation with servo motor high-speed input. The gearboxes are ideal for achieving maximum output torque, and their hollow output shaft connects perfectly with circular flanges and reduces the installation space. Planetary gearheads - stainless steel

Learn More

Geometry / Planetary Gears - Drivetrain Hub

The design of planetary gears is reviewed for spur and helical gears. Spur or helical gears each have their advantages in planetary gearing.

Learn More

Design and Build an in Series Planetary Gearbox with a Ratio

Figure 2: Full Solid Works Assembly of Planetary Gearbox. Design. The carrier plate was machined using the spinner cnc machine and it was manually machined

Learn More

Design and Optimization of Planetary Gearbox for a Formula

Planetary Gearboxes (or Epicyclic gearboxes) have been widely used as one of the better ways to transmit power for high torque applications.

Learn More

Planetary gear design calculations - ouxt.usinedematelas.fr

Planetary gear transmission (PGT) is widely used in the automobiles, helicopters and marine applications. PGT is more advanced than counter-shaft drive because of its higher torque-to-weight ratio, compactness and reduced noise. Design audit gears when pitch line velocities exceed 6,000 meters/min (20,000 ft/min) to ensure optimum safety.

Learn More

How to Pick the Best Planetary Gearbox Manufacturers | Carson

After completing the design process, a product might occasionally need to be revised. We are happy to craft new and creative solutions for applications requiring specific components, even if it means going back to the drawing board. We also won’t charge revision fees, unlike other planetary gearbox manufacturers. 6. NEMA Compliant.

Learn More

Helical Planetary Gearboxes: Understanding the Tradeoffs

Planetary systems split the torque input from the sun gear amongst the planet gears, which in turn transfer torque to a planet carrier connected to the gearbox

Learn More

What are the drawbacks to using a planetary gearbox?

The planetary gearbox design is fairly simple, consisting of a central sun gear, an outer ring (also referred to as an internal gear,

Learn More

Planetary gearbox Design. Question : r/EngineeringStudents

Planetary gearbox Design. Question . I am working on a Planetary gearbox using 4 planet gears. It is for a traction reducers used on Continuous miners in the coal industry. However I have a difficult time as the planet gears doesn’t mesh well with the ring gear. (Imperial units) Ring Gear: Number of teeth: 56 Diametral pitch: 4 Pressure

Learn More

Designing Planetary Gearboxes in Fusion 360 for Robotics

Step 3: Lets Start Making Something! I'm going to design a planetary gear with 4 planet gears and I'm going to use the carriage as the output with screws going out of it as an attachment point. I decided I want a 4:1 gearbox so I used a 20 tooth module 1 gear for sun and planet gears and 60 tooth gear to cut the ring gear.

Learn More

Material Selection for Optimum Design of Planetary Gear Train

The materials utilized for gears are nodular graphite cast iron. The material properties and costing of pinion and gear material were studied, and standard gear

Learn More

Planetary Gearbox Design | Heason Technology | Heason

Planetary Gearboxes have a unique design and way of working. The input and output gears rotate around the pinion or “sun gear”. The centre of the input gear revolves around the centre of the output gear and the input and output shafts are aligned.

Learn More

PDF Design, Analysis and Optimization of Planetary Gearbox: A Review - IJSRDPDF

Key words: Complex planetary gear system, optimization of planetary gearbox, Weight reduction NOMENCLATURE No. of teeth on Gear (Z) No. of teeth on Sun Gear (S) Especially in applications requiring:No. of teeth on Planet Gear (P) No. of teeth on Pinion Gear 1 (P1) No. of teeth on Pinion Gear 2 (P2)

Learn More

Modeling for design simplification and power-flow efficiency

PDF | An approach for design simplification and improvement in power-flow efficiency of an automotive planetary gearbox is presented in this article.

Learn More

High Speed Planetary Gearbox | Carson Manufacturing

Carson Manufacturing's gearboxes offer rotational speeds that range up to 5,000 RPM, with ratios ranging from 1:1 to 10,000:1. Our high speed planetary gearbox uses a well-balanced epicyclic gear system consisting of three equally distributed gears. This gearbox design includes the centrally-located sun gear, the fixed planet gears, and the

Learn More