crusher feed

Animal Feed Crusher Machine manufacturers & suppliers

China Animal Feed Crusher Machine manufacturers - Select 2022 high quality Animal Feed Crusher Machine products in best price from certified

Learn More

Chutes - Outotec

Crusher feed and discharge chutes; Feeder discharge chutes; Tripper chutes; Stacker chutes; Mill feed and discharge chutes; Excellent wear life. Wearback™ chutes are designed with a series of curved and straight ledges allowing material to build up throughout the transfer, forming a layer of material as the wear medium. This so-called rock-on

Learn More

Feed Pellet Crusher

Crushing has a direct impact on both the cost and the nutrition of feed pellets. Our products-SSLG Series double-roller crusher and triple-roller crushing

Learn More

Crusher - an overview | ScienceDirect Topics

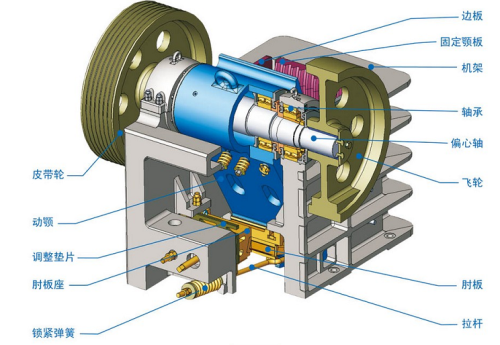

Schematic diagram showing principle of jaw crusher showing the path of lumpy feed ore to fragmented product crushed under high pressure of fixed and moving jaws

Learn More

Cone Crusher Feed Size | Crusher Mills, Cone Crusher, Jaw Crushers

The max.feeding size should be ≤85% of the feed opening size.Otherwise, it will cause: 1. decrease the capacity of the cone crusher Cone Crusher,Cone Crusher Manufacturer,Export

Learn More

Animal feed crusher machine - Sheonghong Machinery

Animal feed crusher machine Capacity(kg/h): 20-50 Power(kw) : 1.5-3.5 Application: Suitable for breeding plants, seasoning shops, soymilk workshops, restaurants, etc. How Animal feed crusher machine works: After the material enters the crushing chamber of the animal feed crusher machine from the feed hopper, it is crushed by the high-speed rotating hammer.

Learn More

Blog: Three reasons why your primary crusher feed contains oversized

The primary crusher is an important part of the mining process, taking the run of mine (ROM) ore and reducing it to a size which can be processed by the downstream operations. However, mining

Learn More

Pedü - Feed Crusher - Science & Technology - Nagaland

Feed Crusher” or “Pedü” is coined in the local dialect which is used to crush raw materials for preparing feeds mainly for animals such as pigs,

Learn More

Crusher (Immersive Engineering) - Official Feed The

This page is about the Crusher added by Immersive Engineering. For other uses, see Crusher. The Crusher is a 3×5×3 multiblock added by Immersive Engineering. It is used for crushing

Learn More

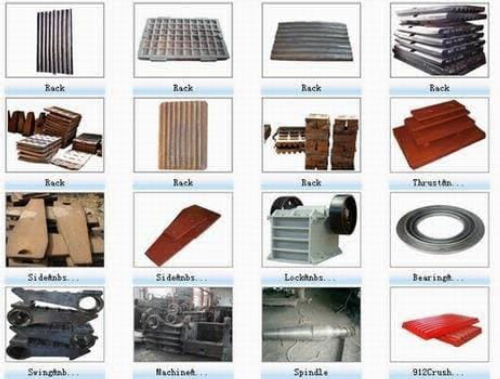

What is a Jaw Crusher? – MEKA Crushing Equipment

This is the second stage of crushing. Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between

Learn More

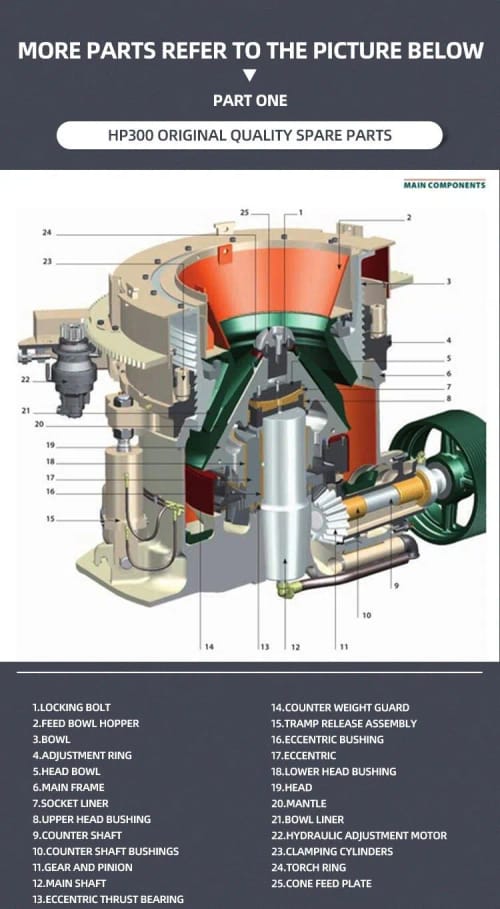

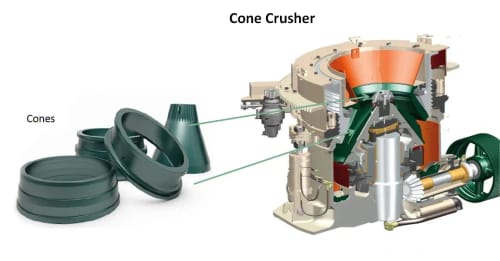

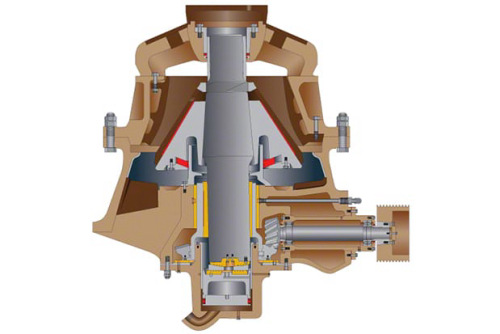

Cone Crushers | McLanahan

The optimum speed of gyration and the large eccentric throw produce two important results: 1) the rapidly closing head catches the falling feed material and delivers the extremely high crushing force and 2) on the other side of the chamber the rapidly receding head allows material to fall freely to the next point of impact or exit the chamber.

Learn More

Common Feed arrangement problems — SRP

Poor feed arrangements affect crusher performance, liner life and the life of mechanical components, so it is crucial that you can identify and deal with

Learn More

Fish feed crusher - 360, 400, 500 - AgriExpo

Fish feed grinder is a machine specialized in crushing materials by the collision between the high-speed hammer and materials. Raw materials in feed crusher

Learn More

Small Feed Crusher Machine for Feed Production Process

SW feed hammer mill is a kind of machine which is specialized used for crushing materials by the collision between the high-speed hammer and materials. The raw

Learn More

Feeding the Crusher - Onetrak

Feeding the crusher · Always check that the crusher is on level ground with no cross fall or you will get uneven feed, cause uneven wear and

Learn More

Jaw Crushers | McLanahan

The Jaw Crusher is designed to handle this feed, but limits are: Do not exceed the F80 rule on top size. This happens at times, just not a steady rate. The fine material size equal to the closed side setting should be removed prior to entering the crushing chamber. A best practice, if possible, is to blend the material arriving from the source.

Learn More

The pros and cons of cone crusher applications - Quarry

Crusher feed should be evenly distributed around the centre of the crushing chamber. Avoid feed segregation where the coarse new feed is on one side of the feed opening and the finer recirculated feed is on the opposite side of the feed opening. 6. Setting should be close to desired product size.

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate. Solution. The first exercise is to determine Q RC from equation Q RC = Q R /K. Step 1

Learn More

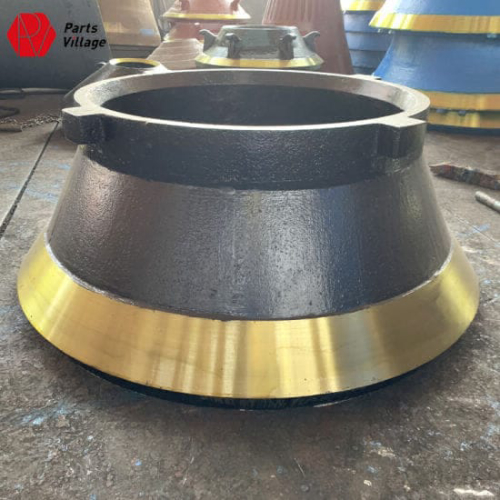

Crusher - Wikipedia

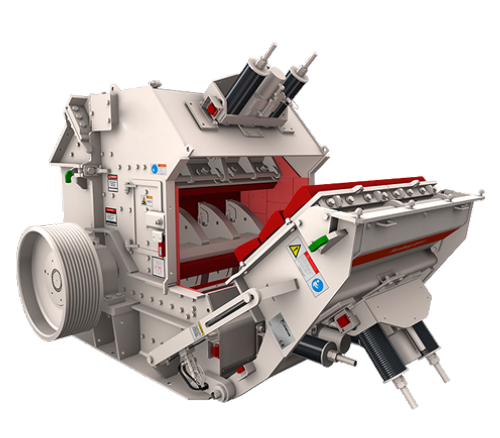

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, For other uses, see Crusher (disambiguation). A feed crusher.

Learn More

Choke Feeding a Jaw Crusher

A crusher is choke fed when the chamber is full and there is material above to keep it full. This contrasts with regulated feed, where the flow

Learn More

Crusher (Immersive Engineering) - Official Feed The Beast Wiki

The Crusher is a 3×5×3 multiblock added by Immersive Engineering. It is used for crushing ores into grit, which is more efficient than normal smelting. Contents 1 Construction 1.1 Bill of materials 1.2 Assembly 1.3 Bill of materials 1.4 Assembly 2 Usage Construction Current Bill of materials 10 Steel Scaffoldings 10 Light Engineering Blocks

Learn More